THE FUTURE OF MAKING

GENERATIVE DESIGN FOR MANUFACTURING WITH FUSION 360

Generative design is a form of artificial intelligence that leverages the power of the cloud and machine learning while accelerating the entire design-to-make process.

Generative design overview video (1:19 min.)

Accelerate your product development process

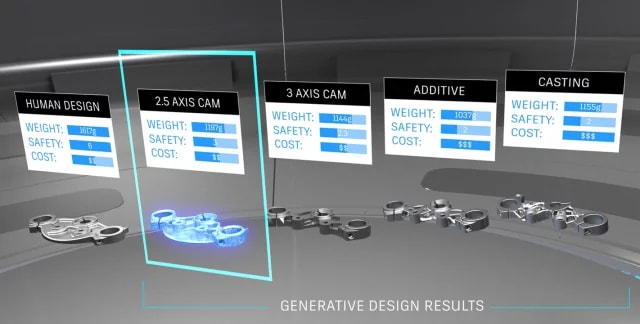

The generative design process explores manufacturing-ready outcomes earlier in your production process, optimized for cost, material, and different manufacturing techniques, so you can get to market faster.

Manufacturing-ready solutions with generative design

Generative design in Fusion 360 gives you the ability to select multiple manufacturing methods to quickly explore numerous solutions for your design and engineering challenges.

-

ADDITIVE MANUFACTURING

Improve design freedom and bring your innovations to the front. Build better quality products in less time while reducing material waste.

-

CNC MACHINING

Take advantage of your shop-floor production capabilities by improving consistency across your 2.5-axis, 3-axis, or 5-axis machines.

-

CASTING

Enable complex shapes, intricate sections, and greater mechanical properties while combining additive, subtractive, and generative design for reduced production costs.

-

INJECTION MOLDING

Optimize the effectiveness of your high-volume injection molding with generative design, achieving a higher production rate with reduced cycle times.

Explore limitless possibilities with generative design

See what the Harvard Business Review has to say about:

- The future of intelligent design automation

- Generative design vs. topology optimization

- Breakthrough innovations with generative design

Benefits of generative design for manufacturing

Helping manufacturers do more, better, and with less.

-

LIGHT WEIGHTING

Quickly identify solutions to minimize mass and material use while maintaining performance standards, meeting design goals, and respecting engineering constraints.

-

PERFORMANCE IMPACT

Evaluate multiple manufacturing methods using generative design and discover solutions to improve and optimize product durability and eliminate areas of weakness.

-

PARTS CONSOLIDATION

Explore a range of design solutions that allow you to consolidate multiple components into solid parts, reducing assembly costs and simplifying your supply chain.

-

SUSTAINABILITY

Meet your sustainability goals by using generative design to lightweight your products, creating less production waste and helping you select more sustainable materials.

Companies using generative design

-

Briggs Automotive Company

Powered by generative design, BAC reinvented the wheel for their latest super-car, reducing weight by 35% while retaining the company's brand identity and optimizing manufacturing for 5-axis machining.

Image courtesy of Briggs Automotive Company

-

Edera Safety

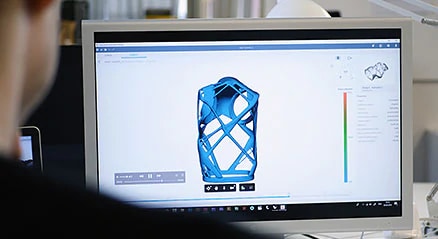

Using generative design technology, adamsfour, an in-house brand at Edera Safety, has created a revolutionary new back-protection system for athletes.

Image courtesy of Edera

-

MJK Performance

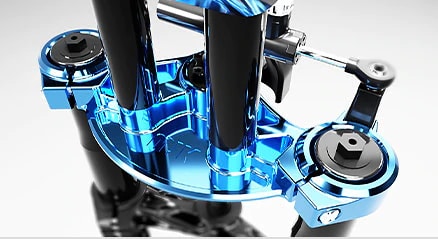

MJK used generative design to create a 23% lighter set of triple clamps for a specialty drag bike that was fully machinable on a 2.5-axis CNC milling machine.

Image courtesy of MJK Performance

-

GENERATIVE DESIGN IN FUSION 360

Produce CAD-ready editable geometry to immediately edit in Fusion 360 or export to your CAD software of choice.

Generative design geometry integrates seamlessly with Autodesk Inventor, maximizing efficiency and collaboration.

The latest on generative design

-

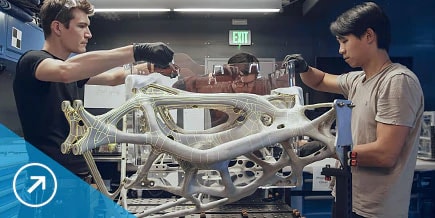

Bringing design ideas to life

Read this Verdict Magazine interview on how transformation in industry technologies, such as additive manufacturing and generative design continue to change the way products are made.

Image courtesy of Airbus

-

Closing the skills gap with generative design

With labor forces struggling to keep up with technological advancements, learn how generative design is bridging the skills gap between design, engineering, and manufacturing.

-

Redefining what’s possible

Indian company Social Hardware used generative design to create a prosthetic device that combines the best features of two very different types of prosthetic limbs.

Image courtesy of Social Hardware

Generative design resources

Access an expanding repository of generative design resources to help inspire new ideas.

Get more designs and faster production through generative design with fusion 360