In the not-too-distant future, robots and humans will work side by side to accomplish things neither could achieve on their own. Maurice Conti, director of Applied Research and Innovation at Autodesk, gives his perspective on the future of robotics.

ROBOT PROGRAMMING SOFTWARE FOR MANUFACTURING

Discover how the collaboration between humans and robots is making a big impact on the manufacturing, architecture, and construction industries.

Manufacturing with robots

-

Additive manufacturing on demand

Port of Rotterdam’s RAMLAB and Autodesk collaborate to pioneer on-demand additive manufacturing for ship repair.

-

Meet Mimus, the curious robot

Mimus is an industrial robot that has no preplanned movements. Instead, it is programmed with the freedom to explore and roam about its enclosure.

-

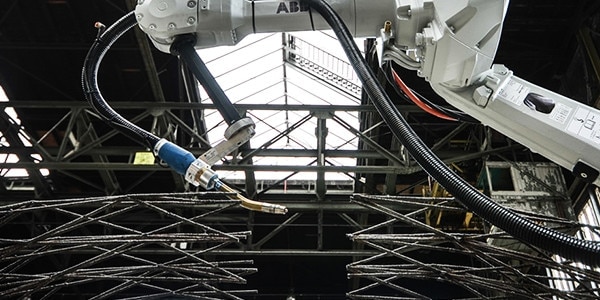

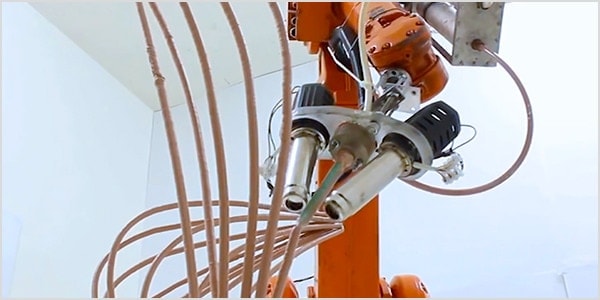

Autonomous 3D-printing robots

Dutch 3D-printing technology firm MX3D is 3D printing a fully functional, intricate steel bridge over water in Amsterdam using industrial multi-axis robots.

-

Generative Design Pavilion

CNC milling, robotic fabrication, and traditional hand-carving workflows were used to build the limestone base of the Generative Design Pavilion.

Customer stories

-

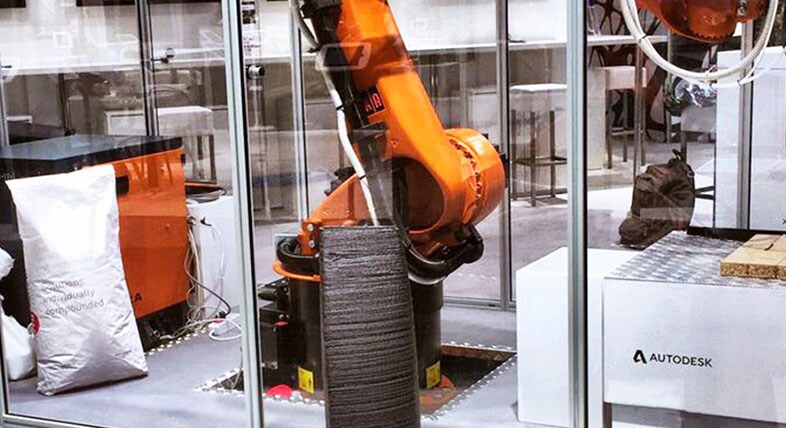

Livrea builds 3D-printed yacht

By connecting cloud design and robotic additive manufacturing, Sicilian boat builders Livrea have made huge strides in building the first 3D-printed yacht. The company has successfully 3D printed the yacht’s hull using advanced, multimaterial, polymer composites.

-

Merlin Magic Making

The creative team at Merlin Magic Making produces attractions for theme parks such as LEGOLAND, Madame Tussauds, and the London Eye. The team uses a robot to mechanize its production and speed up delivery times.

-

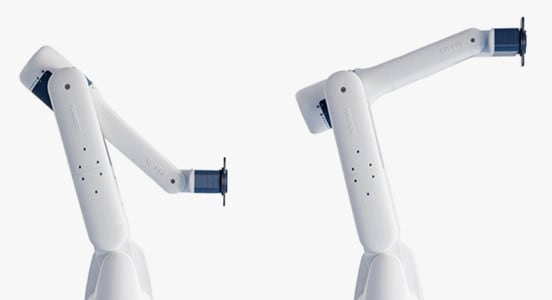

Automata's affordable robotic arm

Traditionally, manufacturers considered robotic arms to be a significant investment. But startup company Automata is changing that perception with the launch of Eva—a lightweight, affordable, easy-to-use robotic arm.

Robotics in manufacturing trends

-

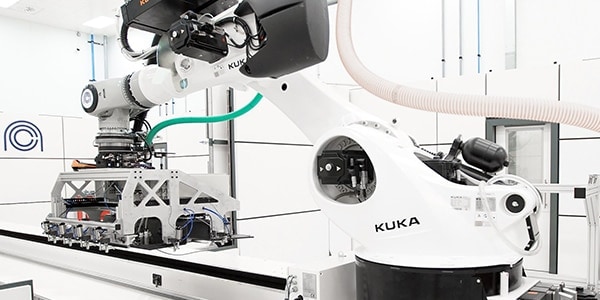

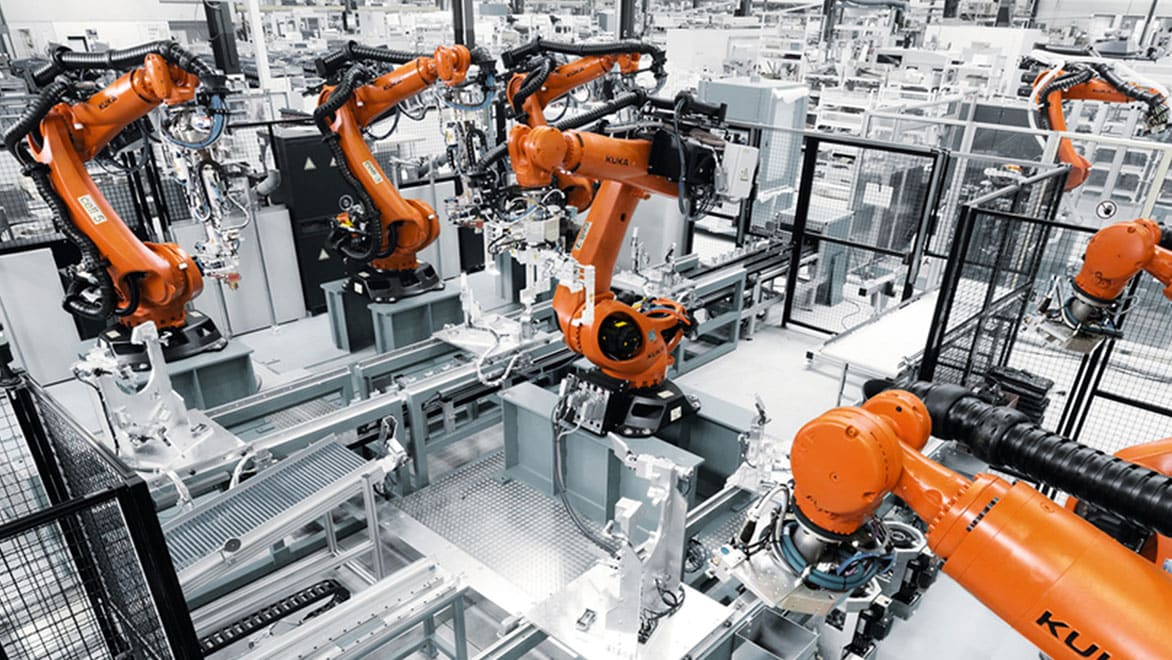

Deciphering Industry 4.0

Autodesk and KUKA Robotics discuss how new digital technologies are changing manufacturing, and what these new technologies can do for smaller companies.

-

Cobots: Intuitive co-workers

Improving the safety of robotic systems will lead to greater human-robot collaboration.

-

Smart manufacturing technology

Learn how robotics, customization, and technologies that connect data to the factory floor is changing manufacturing.

-

Transforming generative design

Learn how the things that have limited us in the past, software, materials, manufacturing methods - no longer do so.

Collaborative research projects

-

SYMPLEXITY is a collaborative project to develop new human-robot solutions for industrial manufacturing.

-

The LASIMM project is developing large, flexible, all-in-one machines on a scalable framework for hybrid (additive and subtractive) manufacturing.

-

HyProCell uses laser-based additive and subtractive manufacturing, enabling machine interaction to optimize workflow and data handling.

PowerMill CAM software for robotics

PowerMill software provides powerful, flexible, easy-to-use tools for offline programming of robots. Get tools to help you optimize robotic paths and simulate virtual mock-ups of manufacturing cells and systems.