PRODUCT DESIGN & MANUFACTURING

What is plastic injection moulding?

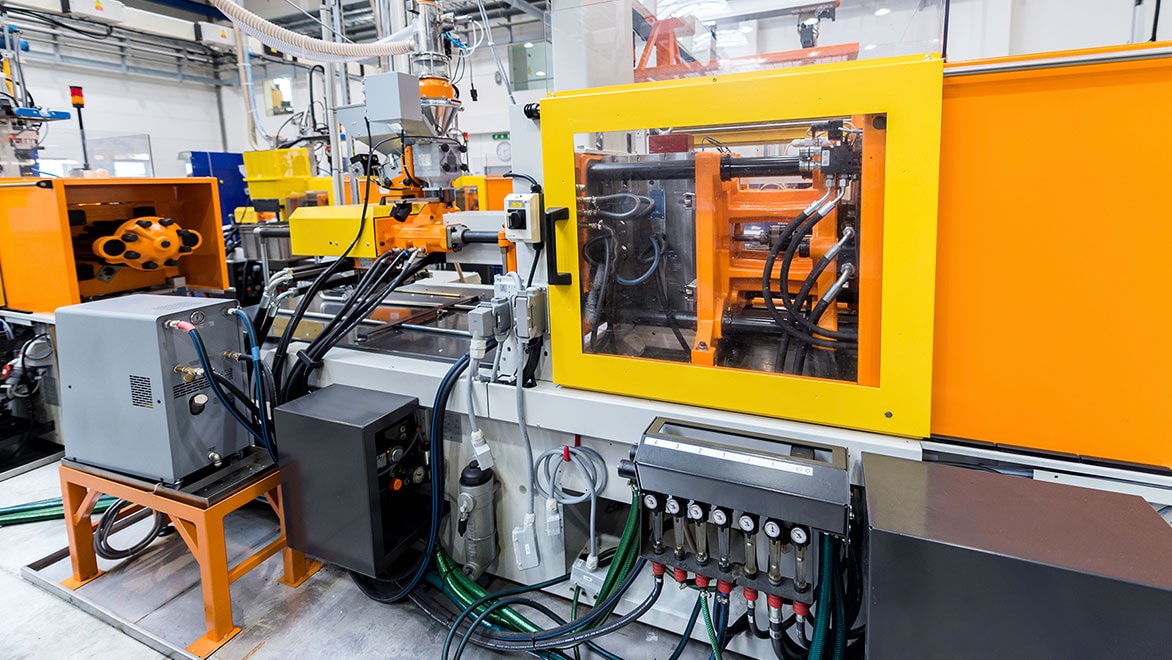

Thermoplastic injection moulding is a method for manufacturing high-volume parts with plastic materials. Due to its reliability and flexibility in design options, injection moulding is used in many industries, including packaging, consumer & electronics, automotive, medical and many more.

What are the most common types of injection moulding processes?

The traditional thermoplastic injection moulding process can be modified to include processes that help to enhance part quality and part design flexibility. Below are some examples:

-

Thermoset injection moulding

Moulding with thermoset materials requires heat or chemical means to cross-link polymer chains.

-

Overmoulding

Overmoulding is an injection moulding process where one material is moulded on top of another.

-

Gas-assisted injection moulding

Inert gas is introduced, at high pressure, into the polymer melt at the end of the injection phase of moulding.

-

Co-injection & Bi-injection moulding

Injection of two different materials using either the same or different injection locations.

-

Microcellular injection moulding

Use of physical blowing agent, chemical blowing agent (CBA) or mould core-back process to trigger foaming of polymer inside the mould.

-

Powder injection moulding (PIM)

Forming technique for producing small components using powders, typically ceramics (CIM) or metals (MIM) and binding agents

What are some advantages of injection moulding?

Injection moulding manufactures high quantities of parts, faster than other manufacturing methods (machining or 3D printing). High accuracy and automated processes encourage identical part creation, promoting low labour costs. Customisation allows flexibility in part design (e.g. moulded-in inserts) and material properties (e.g. colour, clarity, strength and flexibility).

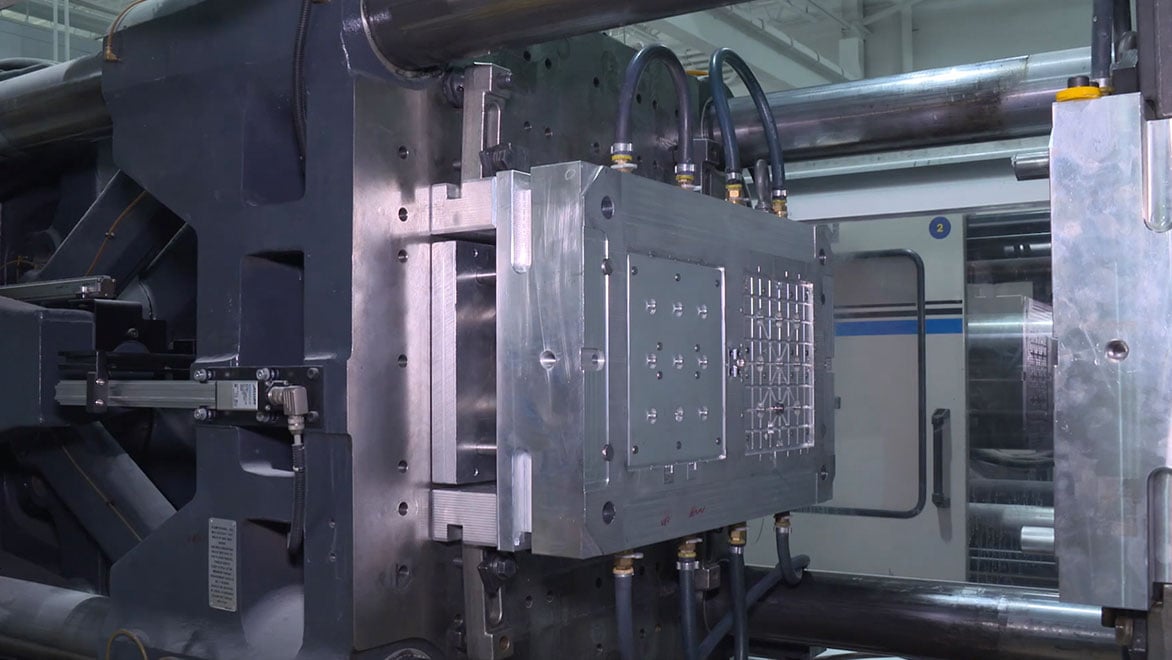

What challenges can there be with injection moulding?

Part designers, mould engineers and other manufacturing stakeholders can all run into their own challenges, which ultimately affect part quality, and they often need to work together to resolve them if not caught in the early design stages.

Some examples of these challenges include material variations, weld lines, sink marks, warpage, long cycle times and incomplete cavity filling.

How does injection moulding simulation software help?

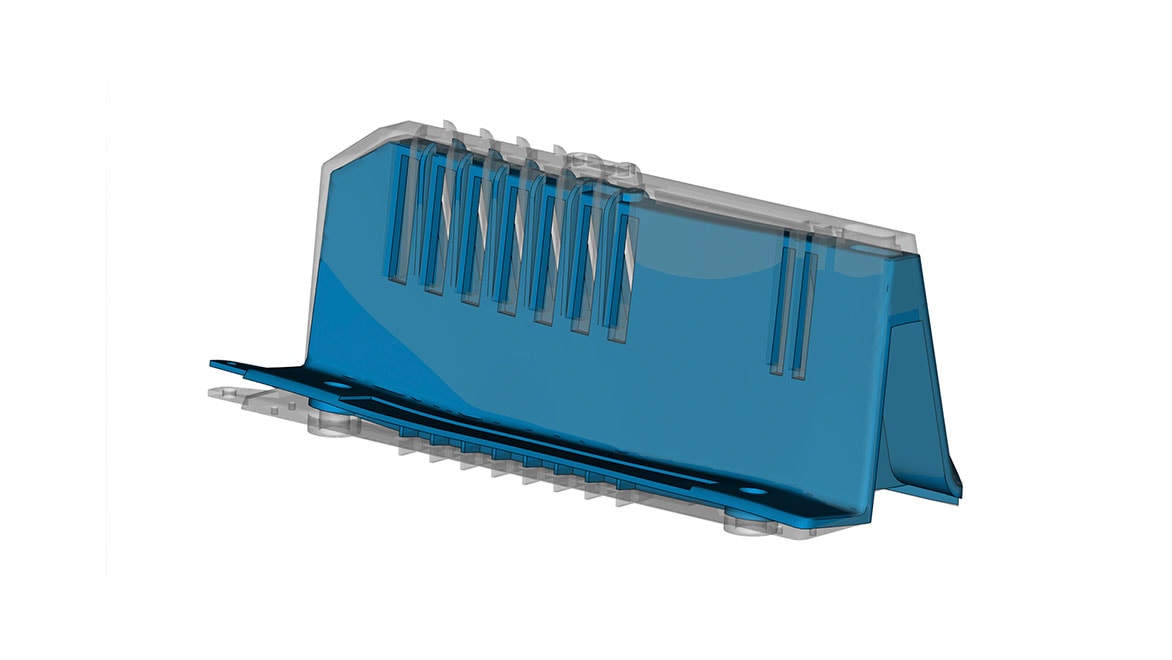

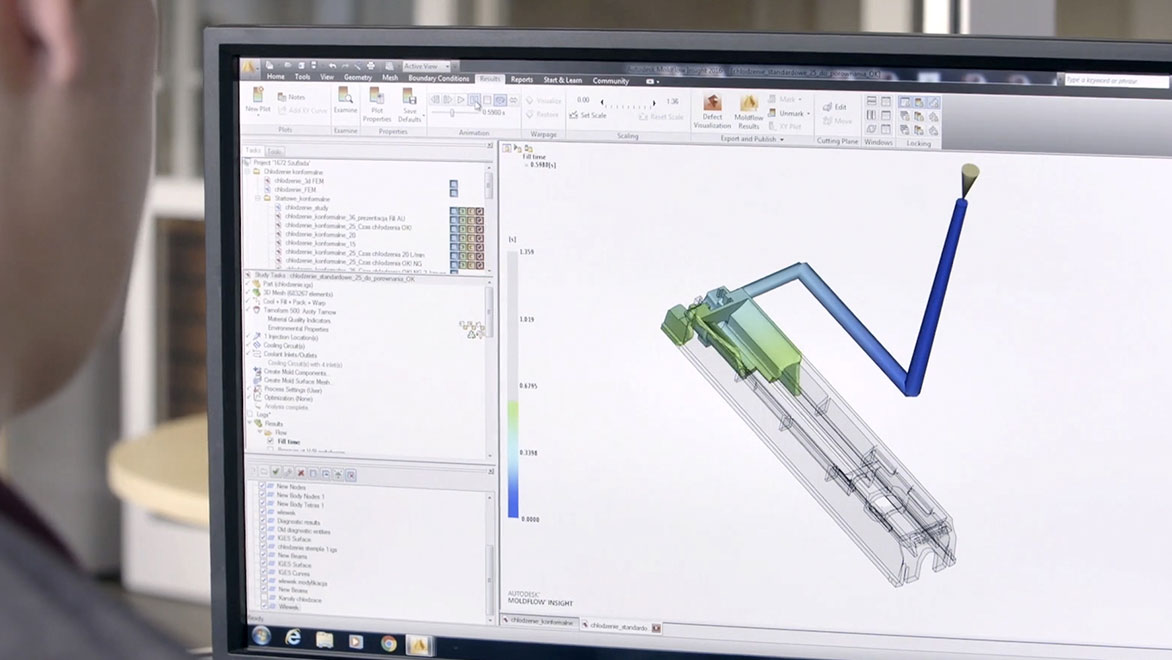

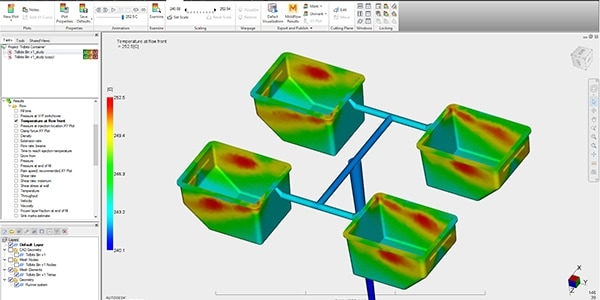

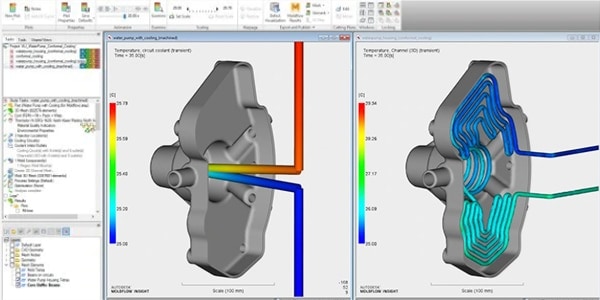

Moulding simulation can help designers and engineers to understand risks early in the design process, giving them the ability to address these before becoming fully invested. Simulation software gives engineers, mould makers and other moulding professionals accurate digital prototyping solutions and help bring better products to market faster.

Moldflow simulation can be paired with other simulation tools, including mechanical stress, vibration, motion, computational fluid dynamics (CFD) and multiphysics, providing a fast, accurate and innovative approach to solving the most challenging design problems.

How can Moldflow injection moulding simulation software help?

-

Predict surface finish defects

Analyse fill patterns and effects of geometry & process setting changes, such as sink marks.

-

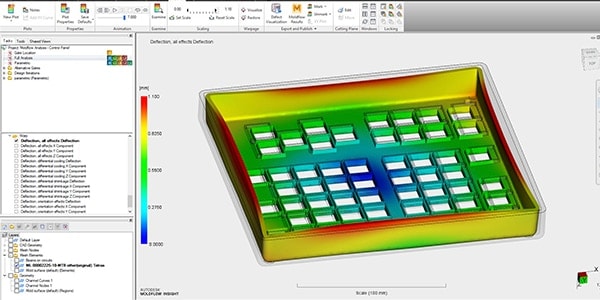

Predict & prevent warpage

Investigate the causes of warpage, then examine options to minimise or correct part deflection.

-

Optimise designs for lightweighting

Analyse and compare advanced materials for lightweighting efforts, such as with automotive components.

-

Reduce part cycle time

Predict part cooling efficiency. Experiment with advanced conformal cooling or induction heating before investing in costly moulds.

Resources for injection moulding simulation

-

Explore simulation through use cases, validation reports and technical papers from our team of experts.

-

Interact directly with current Moldflow Insight users and the Moldflow product team.

-

Read through various articles including injection moulding concepts, simulation how-to's and troubleshooting.

-

Keep up to date with moulding simulation through these engineering-focused blog posts.

-

Interact directly with current Moldflow Adviser users and the Moldflow product team.

-

Watch and read how Moldflow simulation has directly affected product design and manufacturing.

Learn how our Product Innovation Platform lets you more effectively design products and manage product lifecycles.

Explore manufacturing software that may help you machine, print, inspect and fabricate better quality parts, faster.

Free injection moulding software

FOR STUDENTS & EDUCATORS

Student and educators may be eligible to receive a free subscription to injection moulding simulation software, Moldflow Adviser Ultimate.