Worldwide Sites

You have been detected as being from . Where applicable, you can see country-specific product information, offers, and pricing.

Keyboard ALT + g to toggle grid overlay

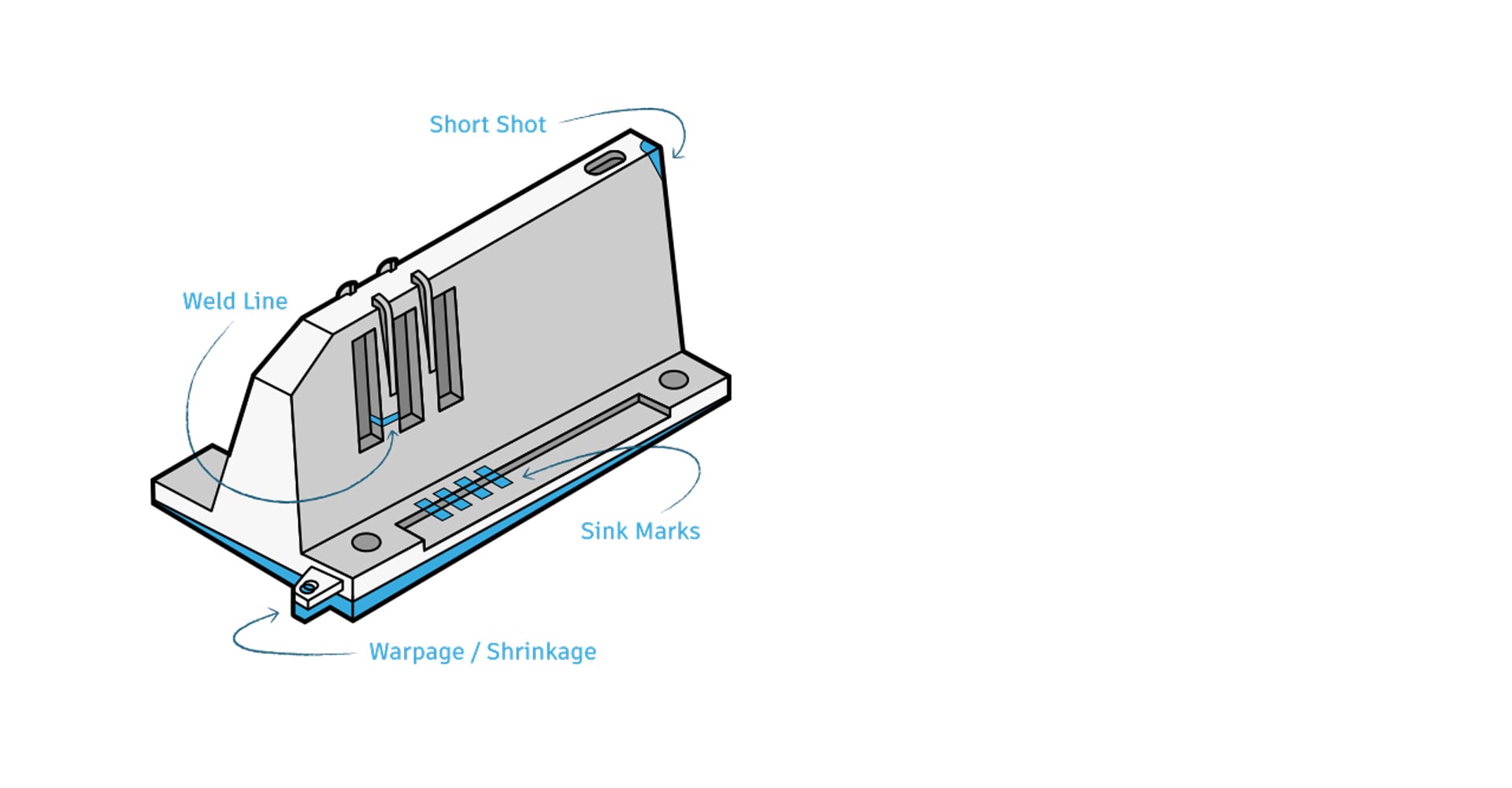

Why part quality matters

Managing part quality in a carefully controlled way sets the stage for more efficient production, more reliable products, and a stronger financial position.

PREVENT DELAYS IN PRODUCTION

Discovering and mitigating issues such as weld lines and warpage long before parts are running protects tight production schedules.

MEET PART SPECIFICATIONS

Understanding how part quality issues affect critical requirements and dimensions enables engineers to design products that meet expectations for performance and durability.

PROTECT PROFIT MARGINS

Consistently outstanding part quality preserves the profitability of every project while strengthening key customer relationships.

Free resources - Learn how to resolve part quality issues with simulation software

-

Predict and prevent warpage

Nothing grinds a project to a halt faster than unexpected warpage. Learn how mold engineers can detect and mitigate the risk of warpage earlier in the design process.

-

A quick guide to weld lines

Weld lines are the Achilles heel of injection molded plastic parts. Learn what causes these defects, why they affect part strength and surface quality.

-

11 factors for mold cooling

Small changes in cooling can have a huge impact on cycle time. Learn more about all the ways you can maximize cooling efficiency to produce higher-quality parts.

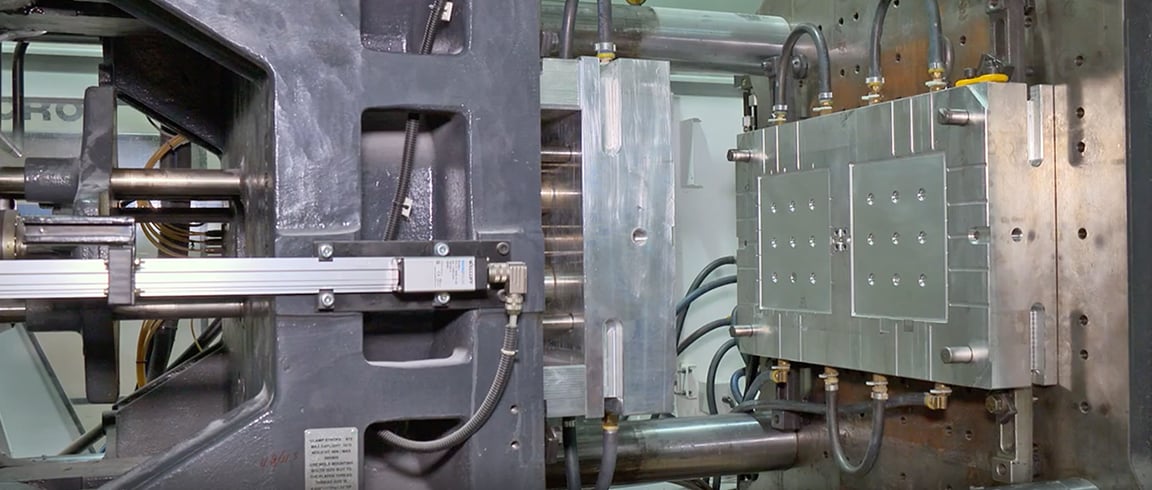

See how Moldflow optimizes part quality

Engineers rely on Moldflow plastics injection molding simulation software to fine-tune plastic part designs, injection mold designs, and manufacturing processes. Watch the videos to see how this powerful application helps reduce and eliminate defects.

-

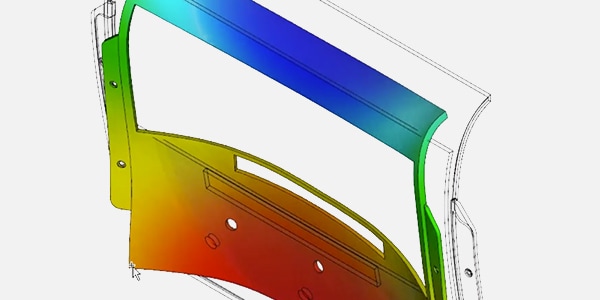

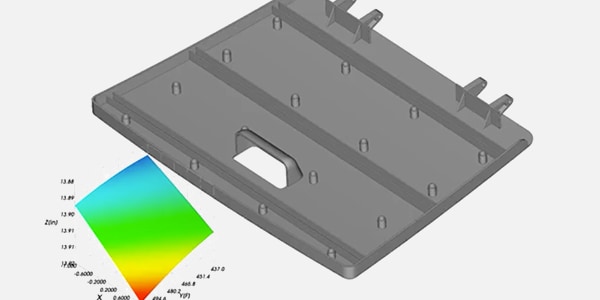

Visualizing warpage

Seeing how warpage is likely to affect a part helps pinpoint the underlying cause and develop effective ways to minimize it.

-

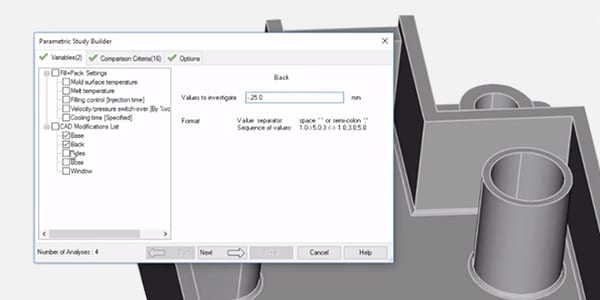

Parametric design studies

Parametric optimization focuses on geometric variables, automating the analysis of various design features to find the best result.

-

Design-of-experiments

This approach allows engineers to run a large set of analyses in parallel to figure out which process settings have the greatest impact.

-

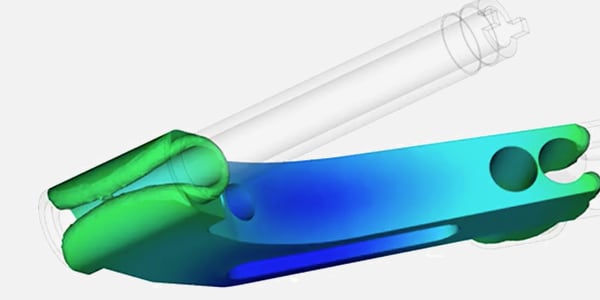

Weld line strength

See how to identify how weld lines affect a part’s performance and reliability as well as develop ways to mitigate these effects.

Talk to us

Speak with one of our manufacturing experts about your specific products and the challenges. We can help you with your hardest problems. Or schedule a time to speak by completing the form.

Call 1-855-612-9998 (toll-free in US)

Call us Monday to Friday, 9am to 5pm or fill in the form and one of our experts will contact you.