Product data management (PDM) is a system for managing design data and engineering processes in one central location. Engineering teams use PDM software to organize product-related information, track revisions, collaborate, manage change orders, generate Bills of Materials (BOMs), and more. With a single source for project data, engineers save time and avoid mistakes.

PRODUCT DATA MANAGEMENT (PDM)

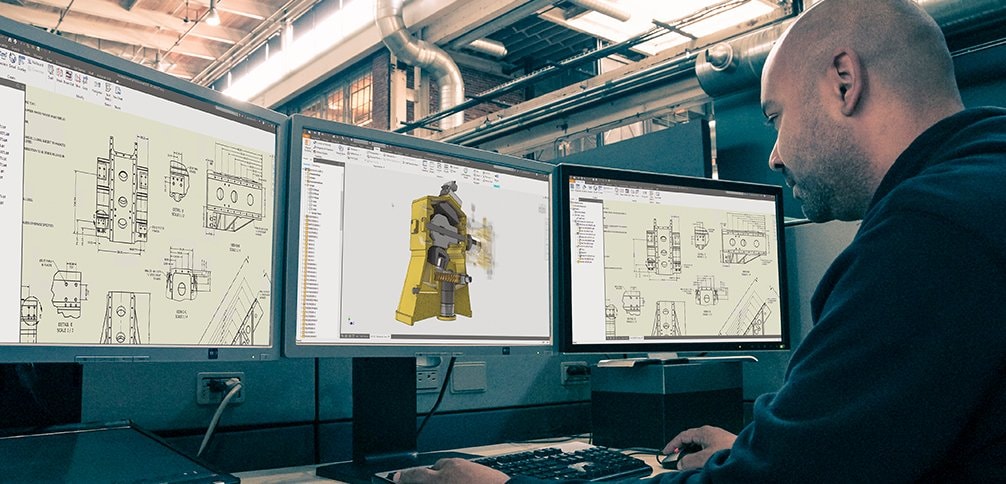

Free up time and maximize engineering efficiency with CAD-integrated product data management software. Autodesk offers modern PDM solutions for engineers, designers, and extended teams.

What is PDM?

Benefits of PDM

According to a Tech-Clarity report, world-class manufacturers are 30 percent more likely to use PDM or product lifecycle management (PLM) to manage their design data.

-

Improved design workflows

Experience direct CAD integration, fast data searching, easily file replacement and reuse, and safe simultaneous access to data. With PDM, your design workflow has never been smoother.

-

Enhanced collaboration

Share 2D or 3D views of your work with others (even those outside your company's firewall) and get comments and feedback directly inside your product.

-

Streamlined processes

Get automated engineering change order, revision control, BOM management, and more. Keep your engineering processes under control with PDM software.

-

Shared knowledge

You don't have to reinvent the wheel. Instead, leverage existing design data. Easily access and configure files you want to replace, reuse, or copy to use in new designs.

Get started with product data management

-

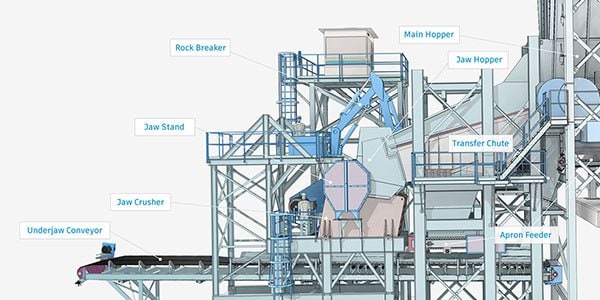

DATA MANAGEMENT & COLLABORATION

Stop wasting time managing design data and get back to making great products. Explore solutions to your data management challenges. Image courtesy of Balzer Pacific International.

-

FREE EBOOK: DEFINITIVE GUIDE TO PDM

Want to learn how to go beyond CAD file management with PDM? Just getting started and need to cover the basics? View this guide—featuring solutions to your data management needs.

-

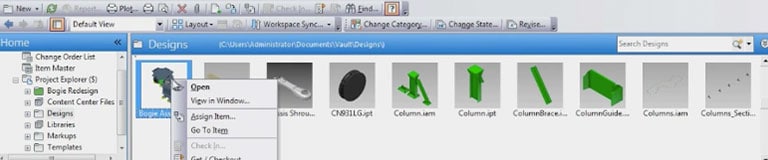

DEVELOP A PDM STRATEGY WITH AUTODESK VAULT

Watch this recorded webinar to learn how to bring together all the engineering data and documentation at your company with Autodesk Vault.

Key PDM capabilities

Product data management software can help you create better designs, reduce errors, and build a more efficient development cycle with features including:

-

CAD file management

Take control of your valuable design files with PDM. Direct CAD-integration keeps your data in sync in real time.

-

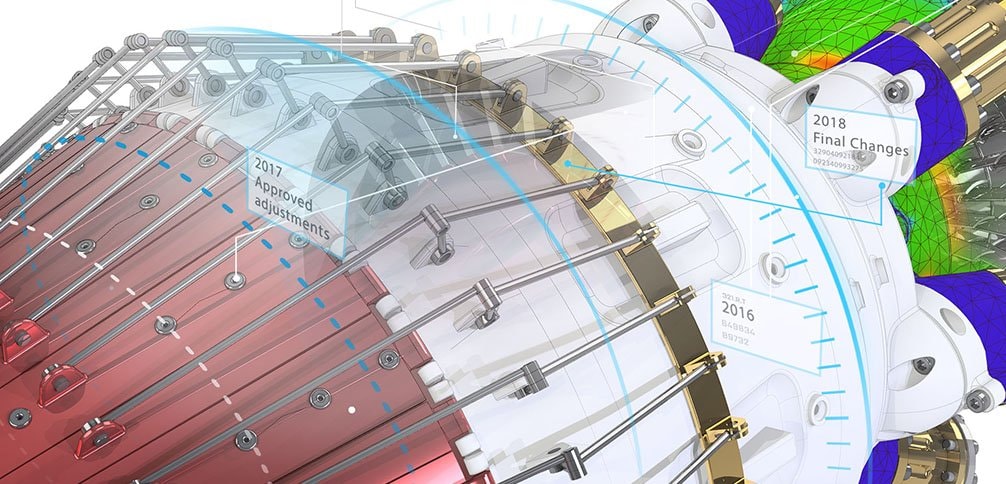

Revision control

Automatically capture the revision history on documents as you work. Never lose track of changes.

-

Business system integration

Integrate design data with systems like MRPs and ERPs.

-

Access control

Strengthen data security by controlling access with permissions for version control and retrieval.

-

Engineering change orders

Easily manage engineering change orders (ECOs) with a workflows that help automate the process.

-

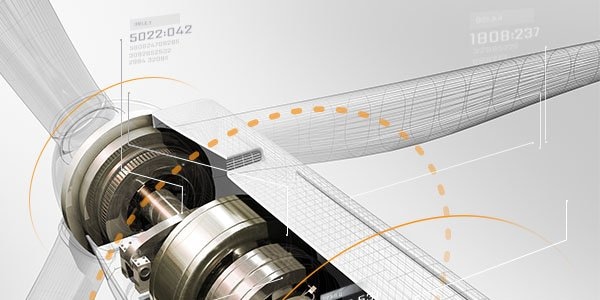

External collaboration

Share 2D or 3D views of your work with others and get comments and feedback directly inside your product.

Autodesk PDM software

-

Product data management software—available as Vault Basic, Vault Professional, Vault Office

-

-

Software for 2D and 3D CAD. Subscription includes AutoCAD, specialized toolsets, and apps.

-

Get Inventor + AutoCAD + Fusion 360 + more—Professional-grade tools for product development and manufacturing planning

-

Powerful BIM and CAD tools for designers, engineers, and contractors, including Revit, AutoCAD, Civil 3D, Autodesk Forma, and more

-

Professional-grade product design and engineering tools for 3D mechanical design, simulation, visualization, and documentation.

Learn more

How is PDM software used?

-

GIFFIN

Automatically track revision history

Functions of PDM systems like file searchability and version control have enabled this integrated finishing process solutions firm to better service the automotive industry.

-

OSGOOD INDUSTRIES

Improve design efficiency

This process equipment manufacturer has improved product development productivity by simplifying data management workflows and expanding access for suppliers and extended teams.

-

JOY MINING

Facilitate collaboration

PDM software helps Joy Mining Machinery improve collaboration and productivity for 400 engineers at 13 engineering sties on 5 continents.

PDM scalability

Manage data anytime, anywhere. Some PDM tools allow for scalable, seamless global replication so you can keep your product-related information in sync across multiple sites. Additionally, collaborate externally with 2D or 3D views of your work that others can comment on directly inside your product.

Additional PDM resources

-

Learn the basics of product data management in this introductory eBook.

-

See how PDM software manages data and processes with the cloud for collaboration with outside customers and partners.

-

Discover how to capture and reuse engineering knowledge with fewer complications and better results.

-

Which product development challenges can benefit from PDM strategies? Read this infographic to find out.

-

Stay up-to-date on the latest Vault updates, tips, and tricks.

-

Find documentation, tutorials, downloads, videos, and more resources.