Fusion 360 with PowerMill® 2022 CAM software offers background verification of NC programmes and toolpaths, enhanced projection finishing, improved toolpath limiting, a faster interface and more.

Features

-

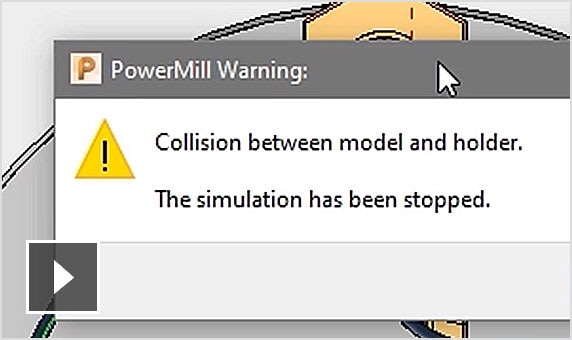

Background verification

Save time by verifying NC programmes and toolpaths in a background process. (video: 1.46 min.)

-

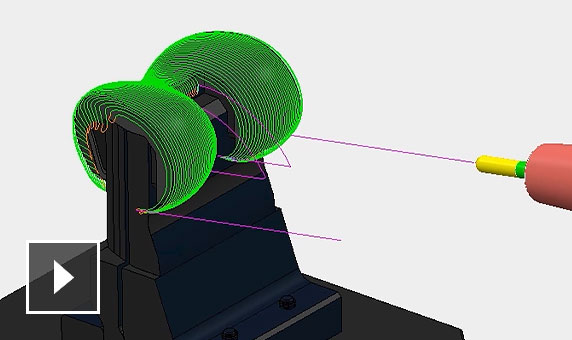

Enhanced projection finishing

New range controls simplify the creation of plane, line and point projection finishing toolpaths. (video: 1.24 min.)

-

Quality of life improvements

New macro security, better toolpath limiting and a faster user interface. (video: 3.07 min.)

-

Finishing toolpaths exclude flats

Automatically exclude planar surfaces from certain finishing toolpaths so they can be machined separately. (video: 1.20 min.)

-

Flat machining

Improved flat area detection creates more accurate Raster and 3D Offset finishing toolpaths. (video: 1.30 min.)

-

Constant Z with undercuts

Simplify machining parts with undercuts by using Constant Z with improved collision avoidance. (video: 1.03 min.)

-

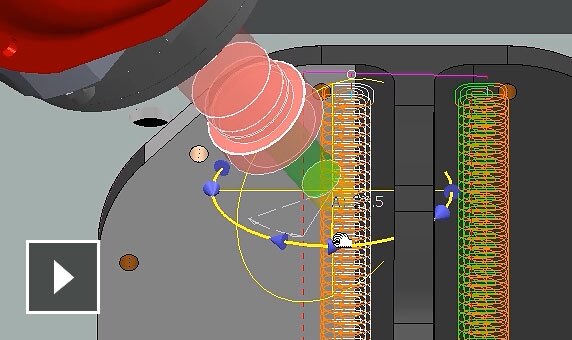

4-axis collision avoidance

Automatic collision avoidance can now be used with 4-axis and rotary toolpaths for increased safety. (video: 1:28 min.)

-

Projection ranges

Access advanced settings to control the extents of Surface and Curve Projection toolpaths. (video: 1.13 min.)

-

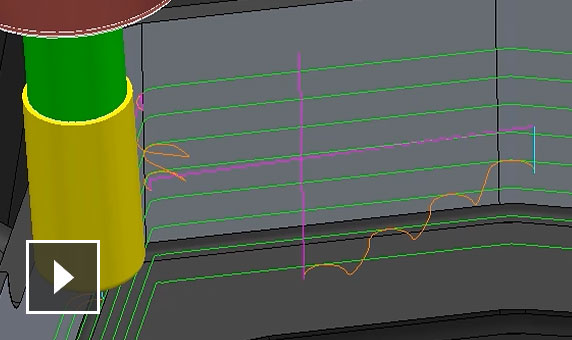

Staggered start points

Redistribute toolpath start points for smoother machine motion and improved surface finish. (video: 1.23 min.)

PowerMill 2021

-

Roughing collision avoidance

Automatic collision avoidance using 5-axis machine motion is now available for area clearance toolpaths. (video: 1:17 min.)

-

DMC for area clearance

Use dynamic machine control in PowerMill to edit the tool axis for localised regions of area clearance toolpaths. (video: 1:18 min.)

-

Faster collision drawing

The calculation and display of colliding toolpath sections is now multi-threaded and up to 68% faster. (video: 4.09 min.)

-

Speed improvements

Start machining parts sooner with faster toolpath calculations, shorter project opening times and more.

-

Faster model filleting

Model filleting respects active boundaries, resulting in up to 90% reduction in calculation times.

-

Additive updates

Improved strategies include faster profiling and a new alternating raster option for stronger parts.

-

Steep and Shallow ordering

Enhanced ‘top first’ ordering of toolpaths in PowerMill including steep and shallow produces safer, more reliable results.

-

Improved arc fitting

More accurate toolpath arc fitting improves machine motion, reduces cycle time and increases part quality.

-

Safer collision avoidance

Automatic tool axis updates using ‘edit within region’ now produces better quality results up to 98% faster.

-

Steep and Shallow enhancements

Improvements to steep and shallow finishing result in increased surface finish quality.

-

Smoother collision avoidance

Automatic collision avoidance now finds and avoids more issues, with safer, smoother 5-axis motion.

-

Safer Optimised Constant Z

Constant Z toolpaths produce better quality outcomes, including in cases where form tools are used.

-

Combined profile and raster DED

Combine profile and raster strategies in a single toolpath for better-quality additively manufactured parts.

PowerMill 2020

-

Speed enhancements

Reduce programming time with faster toolpath calculation, simulation and verification.

-

Faster leads and links

Leads and links calculations now use multi-threading for even faster processing times.

-

Uphill corner finishing

Machine steep corners with uphill cutting for more stable cut conditions and better surface finish.

-

More model export options

Export CAD models using a wider selection of file formats to improve collaboration across teams.

-

PowerMill Viewer

View, analyse and simulate project content on multiple computers at no additional cost.

-

Improved model filleting

Automatically add fillets to internal corners in finishing toolpaths to help minimise damaging tools.