HUNZIKER BETATECH

Modernizing aged water infrastructure using High-Performance BIM Workflows

THE FUTURE OF MAKING

Share this story

Project Overview

Hunziker Betatech AG’s engineering team was tasked with not only renovating two aged wastewater treatment plants located in the canton of Zurich, Switzerland, but also combining them at a single location in order to meet new requirements. Particular challenges the team had to tackle were space constraints, stringent regulation that led to tripling purification output, compliance with new environmental laws, and the need to carry out the project without interrupting service. This is a task that could only be accomplished with digital planning tools.

- Main challenge: Limited building space

- Project: ARA Zimmerberg

- Asset owner: Association ARA Zimmerberg

- Design firm: Hunziker Betatech AG

- Level of investment: CHF 131.5 million (≈USD 143 million)

- Completion: 2027

BIM for Plant Engineering at ARA Zimmerberg

More than 60,000 people live in the communities of Horgen, Oberrieden, Rüschlikon, and Thalwil on the scenic shores of Lake Zurich. To date, two plants in Horgen and Thalwil have been in operation to treat those communities’ wastewater. Both need to be renovated after about 50 years in operation so that they can withstand further population growth and a sustainable future strategy.

The ARA Zimmerberg association decided on a large-scale plant designed at the Thalwil site, which will be able to treat 800 liters of wastewater per second serving up to 78,000 inhabitants. This is the approximate predicted load for 2050.

The engineering firm Hunziker Betatech AG was commissioned the project. The engineering team used digital modeling with BIM workflows for the feasibility analysis.

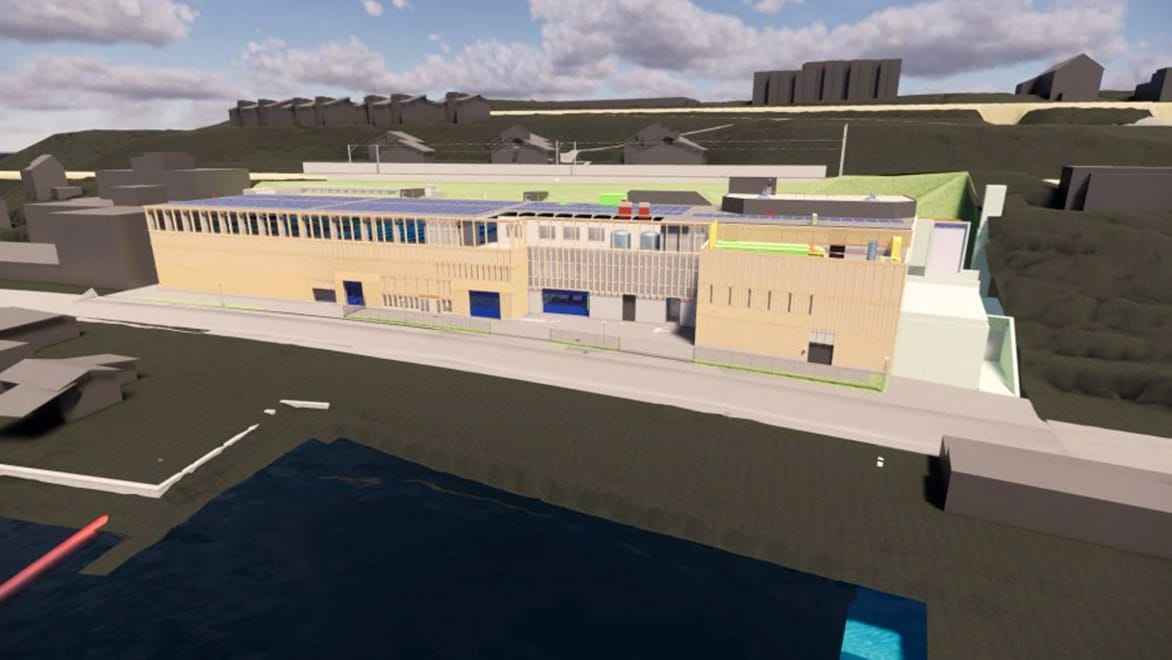

Model of the new WWTP Zimmerberg: project video

Multiple challenges - One solution: BIM

The biggest challenge for the planners at Hunziker Betatech was to use the smallest construction area possible for the plant, since the ARA Zimmerberg construction area is limited on all sides: by residential dwellings, railroad tracks, and Lake Zurich itself.

At the same time, the plant's capacity was to be tripled (merger and respective capacity reserve up to expansion target). Moreover, a new water protection regulation has also come into force requiring an additional purification stage. Since the water is discharged into Lake Zurich, the new regulation requires an additional step to treat contaminants of emerging concern such as traces of pharmaceuticals, which are becoming more common in this type of water streams.

As the project makes progress, the construction phase itself will be particularly challenging, as it will need to take place while ARA Thalwil is in operation. To achieve this, the engineering team has planned a complex construction sequence making use of temporary structures. The building installation area is to be built on a special platform above "Seestraße".

WWTP Thalwil today, construction site of the new WWTP Zimmerberg

“The project was a technical challenge. We had to utilize every centimeter to meet all the requirements.”

—Dominik Börrnert, Head of Digital Planning, Hunziker Betatech AG

Digitalization Leads to Achievement of Sustainability Outcomes

"Without the use of digital solutions, this project could not have been executed. With traditional 2D planning methods, it would have been impossible to plan and build this wastewater treatment plant in the long term. Only with digital 3D planning tools are we able to efficiently use every centimeter of the construction area and approach the project from the technical and legal angles," explains Dominik Börrnert, Head of the Civil Engineering Division and Head of Digital Planning at Hunziker Betatech.

Using ReCap Pro, the Autodesk solution for reality capture, a 3D point cloud was created from digital data captured using stationary scanning technologies. Imported into Revit, this rich data set is then used to generate an existing conditions model that accurately depicts the project’s built and natural environment. The engineers used 3D scanning with Recap in Revit. The planning of the architecture and the structural model was done in Revit, while Civil 3D was used for planning of the construction pit and Plant 3D for the plant model. A CFD simulation was created for the digestion towers.

ARA Zimmerberg: construction phase

The engineers conducted a shading study to ensure that residents would not miss out on daylight and lake views due to construction. The planned canopy and exhaust air purification via biofilters ensured there would be no noise and odor emissions. And to make sure the building did not look like a wastewater treatment plant, the facade was finished in Swiss wood, to blend in discreetly with its surroundings.

“This project could not have been realized without digital 3D planning tools.”

—Dominik Börrnert, Head of Digital Planning, Hunziker Betatech AG

Collaboration Improves Construction Process

While using Revit and enabling BIM workflows, all project participants had a better overview of the various construction stages and planning levels. Continuous collaboration between contractors was essential due to the limited construction area.

Project models were made available through BIM 360, partly with the use of VR glasses allowing that everyone, from structural and civil engineering, plant construction, and electrical engineering, to the building owner and operator—and even area residents— had a uniform view of the plans. This not only saved time but was especially important for the planned reconstruction during ongoing operations.

ARA Zimmerberg: virtual tour

“We were able to find joint solutions to over 300 coordination tasks through collaboration with BIM 360. Otherwise, some of them would have probably only been visible during the construction phase.”

—Dominik Börrnert, Head of Digital Planning, Hunziker Betatech AG

Summing Up

- The feasibility of the complex construction project could only be proven with digital 3D planning.

- More than 300 coordination tasks were completed through collaboration with BIM 360 and the use of VR technology before construction began.

- The project scored 88 percent in the "Standard for Sustainable Building Switzerland," thanks to digitalization and collaboration of all contractors.

The Result: A State-of-the-Art Water Treatment Plant Thanks to BIM

Using digital planning tools, the engineers at Hunziker Betatech succeeded in overcoming the technically demanding challenges: limited building space, increased output, reconstruction during operation, new environmental laws, and sustainable infrastructure construction.

The newly applied membrane process allows for a very compact design with more purification capacity; instead of the usual 54 square meters per resident, the space requirement has fallen to 19 square meters per resident.

The filtration unit was modernized to up to 0.04 µm which will be able to remove viruses from wastewater in the future. In addition, over 80 percent of organic trace substances can be eliminated with powdered-activated carbon direct dosing (fourth purification stage).

The innovative energy concept uses all available kinds of energy. By using turbines and a photovoltaic system, the plant produces eco-friendly electricity. The resulting gas from purification plants is processed into biogas and fed into the local gas network. In this way, the energetic potential of the gas from purification plants is fully exploited. Approximately 0.55 GWh/year is used, which reduces the emissions from fossil fuels in the catchment area by 170 tons CO2 per year. Finally, the process heat is recovered from the purified wastewater.

The result is a more sustainable and cutting-edge treatment plant in Switzerland, with a unique combination of all energy sources. Construction is planned to start in 2022, and ARA Zimmerberg will be commissioned in 2027.

Benefits of Autodesk solutions for plant design

Deliver higher quality and better performing plants