DESIGN TO MANUFACTURING:

TOLERANCE ANALYSIS SOFTWARE

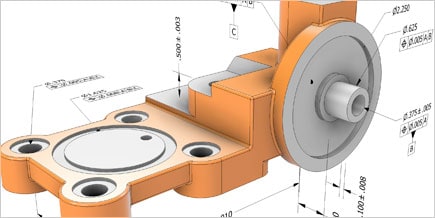

The Autodesk Product Design & Manufacturing Collection includes robust tolerance analysis software to quickly analyze 3D models for proper fit and function.

DESIGN TO MANUFACTURING:

The Autodesk Product Design & Manufacturing Collection includes robust tolerance analysis software to quickly analyze 3D models for proper fit and function.

Tolerance analysis is the process that analyzes dimensional variations in mechanical parts and assemblies based on predefined tolerances. The results enable designers to ensure assembly fit without spending too much time and money on machining.

Components must be designed within specific dimensions–or manufacturing tolerances–so that when they are manufactured, they fit well together. Tolerance analysis before producing a component helps designers save cost and time by avoiding excessive machining operations for tighter tolerances.

Autodesk Tolerance Analysis overview: (video: 2:12 min.)

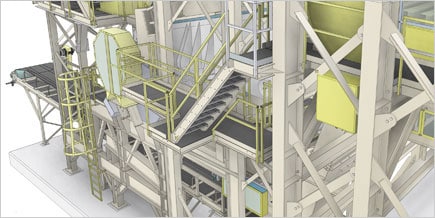

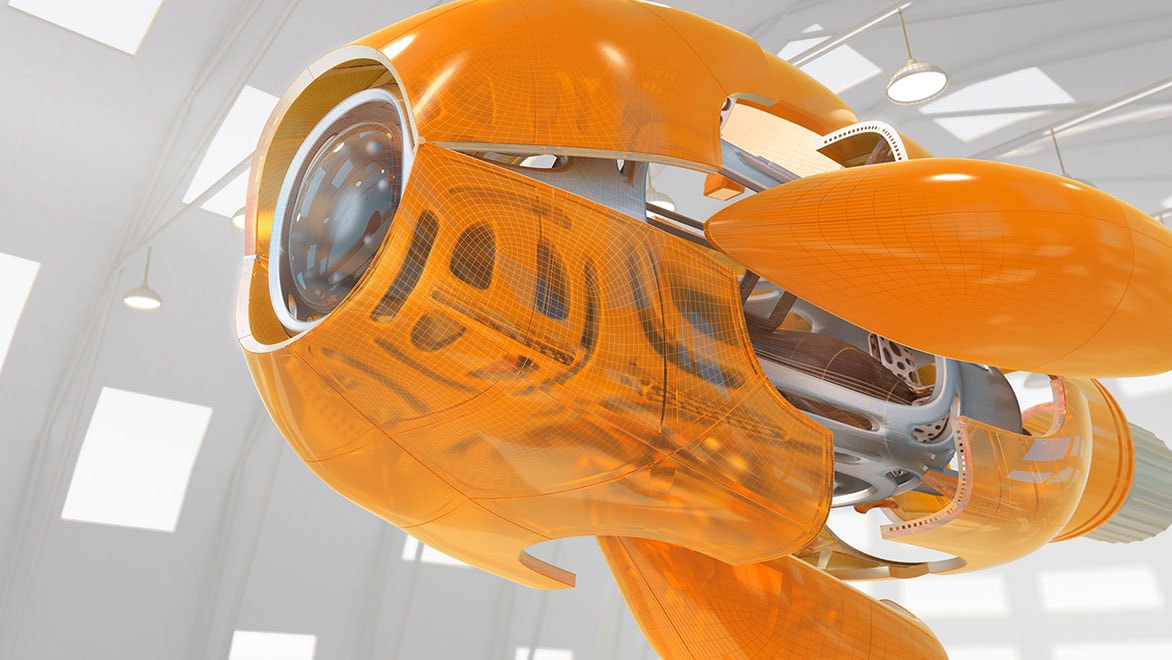

The future of design to manufacturing relies on the use of one integrated solution. See how the Product Design & Manufacturing Collection delivers ways to accelerate product development, streamline mechanical tolerance analysis, generate multiple CAD-ready solutions based on real-world manufacturing constraints, seamlessly connect design and manufacturing teams, and more.

Connect data, processes, and people throughout the design-to-manufacturing workflow. Save on manufacturing costs with Inventor Tolerance Analysis software, only available in the Product Design & Manufacturing Collection from Autodesk.

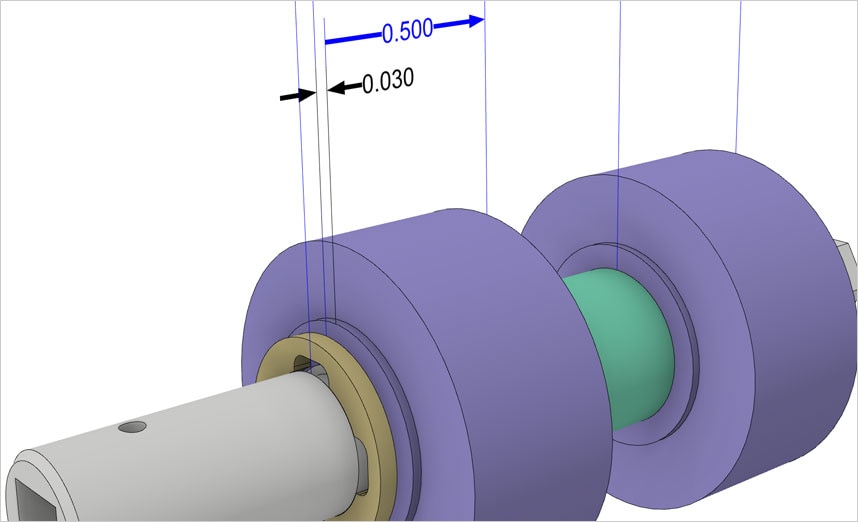

Inventor Tolerance Analysis software allows for easy reporting on the tolerance stack-up of designs.

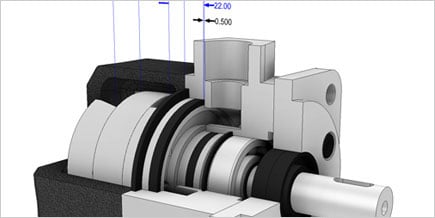

Inventor Tolerance Analysis software eliminates the need for hand calculations and spreadsheets. It automates analysis of critical design areas to satisfy manufacturing objectives.

Image courtesy of Balzer Pacific Equipment Co.

Tolerance stackups are automatically detected as you select the components you are focusing on. Use model-based definition capabilities to edit built-in tolerance values, streamlining your process.

Reduce tolerance issues during manufacturing by running an analysis of the geometric dimensioning and tolerancing (GD&T) in your 3D model.

Easily communicate tolerance analysis findings with partners or stakeholders. Built-in reporting allows you to quickly create a full summary including images, tolerance objectives, and results.

Drive more efficiency into your mechanical design workflow, for any industry and help your designers do their best work with the Product Design & Manufacturing Collection.

Make informed decisions about manufacturing tolerances through improvements to mechanical fit and design performance.

See how the Product Design & Manufacturing Collection works together and how each component enhances the mechanical design process.

Learn how to fully use the Inventor Tolerance Analysis software in the Product Design & Manufacturing Collection from Autodesk.

Use this Autodesk Knowledge Network tutorial for a complete overview of the Inventor Tolerance Analysis software in the Product Design & Manufacturing Collection.

As a CAD-embedded tolerance stackup analysis solution, Inventor Tolerance Analysis software helps streamline the entire design-to-manufacturing process. It supports worst-case, general statistical, and Root Sum of Squares (RSS) analysis methods. This software automates tolerance stack-up tasks that are typically handled by spreadsheets, including calculating the effects of geometric tolerances, clearances around fasteners and pins, statistical results, and managing product requirements.

With Inventor Tolerance Analysis software in the Product Design & Manufacturing Collection, stackups automatically capture the relationships defined in the assembly model. If you use model-based definition capabilities, you can edit tolerance values directly inside the program, further streamlining the process between design and manufacturing.

Inventor Tolerance Analysis software includes multiple features to streamline the design-to-manufacturing process. Reduce tolerance issues during manufacturing by running an analysis of the geometric dimensioning and tolerancing (GD&T) in a 3D model. Calculate the worst-case, RSS, and statistical results of the analysis, and report metrics for statistical results as Cpk, Sigma, DPMO, or Yield. You can also generate reports to communicate analysis results and cost-control efforts to manufacturing and quality engineers.

A Product Design & Manufacturing Collection subscription license lets you choose single-user or multi-user access, for an economical way to get the mechanical design software you need. The collection’s flexible term lengths also let you scale up and down to meet changing business needs. Your subscription includes all product maintenance, upgrades, and technical support, so you can be sure your software is protected. You won’t have to manage multiple product licenses and you can download and install the software you want, whenever you like. In this way, you can scale your business as demand dictates.