ODICO

From gust to gale: Manufacturing robots speed wind farm construction

THE FUTURE OF MAKING

Share this story

Flexible robotics technology improves wind turbine manufacturing efficiency

Denmark has long been a world leader when it comes to renewable energy—the country sources almost half of its electricity consumption from wind power alone. Now manufacturing robots from Danish company Odico are set to transform this pioneering industry even further. The company is bringing robotic precision to wind turbine manufacturing, helping its customers reduce risk and triple productivity. And by enabling frontline workers to build designs from a tablet, Odico’s technology helps drive agile, continuous improvement in the booming renewable energy sector.

Precision matters

Pushing a drill bit through a sheet of metal may seem a mundane thing, but when that metal is attaching a 12-ton aluminium blade to a wind turbine in the North Sea, the way the holes are bored matters quite a lot. Get the placement wrong by a millimetre and months of design, fabrication and assembly work could be wasted.

Stopping expensive and painstakingly engineered components from landing in the scrap heap is part of Odico’s mission. Founded in 2012 in Odence, Denmark—home to a thriving cluster of robotics companies—the company specialises in advanced robotics that bring manufacturing technology to the construction industry. Odico develops super-agile, mobile manufacturing robots that can be recalibrated on the fly. Each robot can triple in-factory productivity for companies specialising in smaller production runs, making it perfect for wind turbine construction.

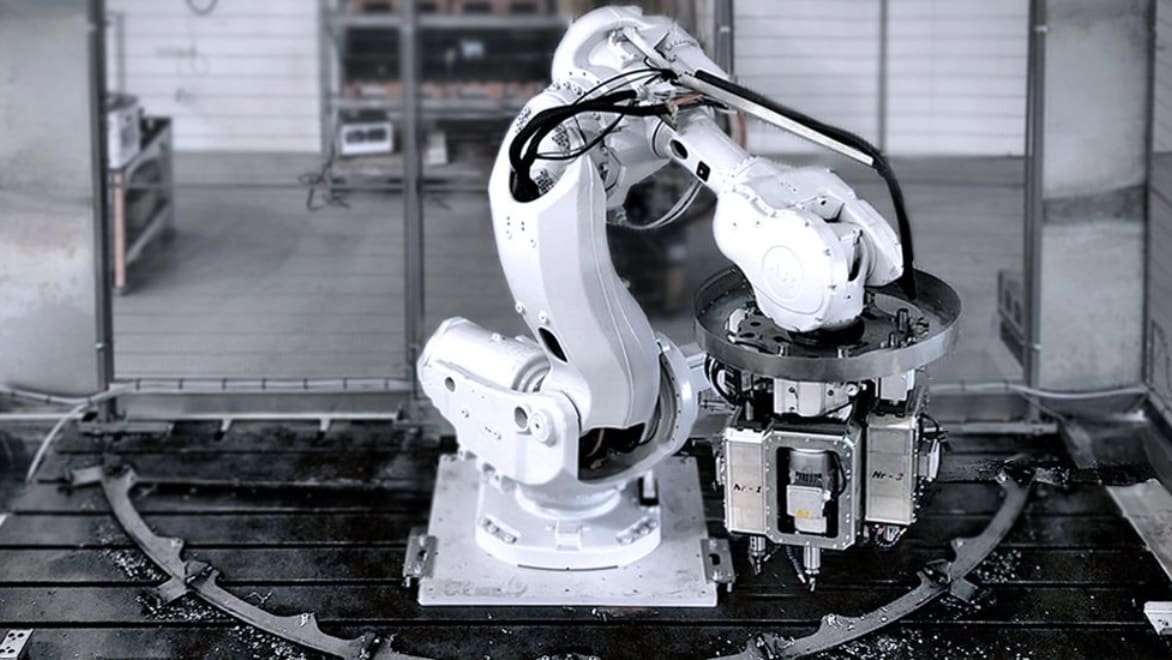

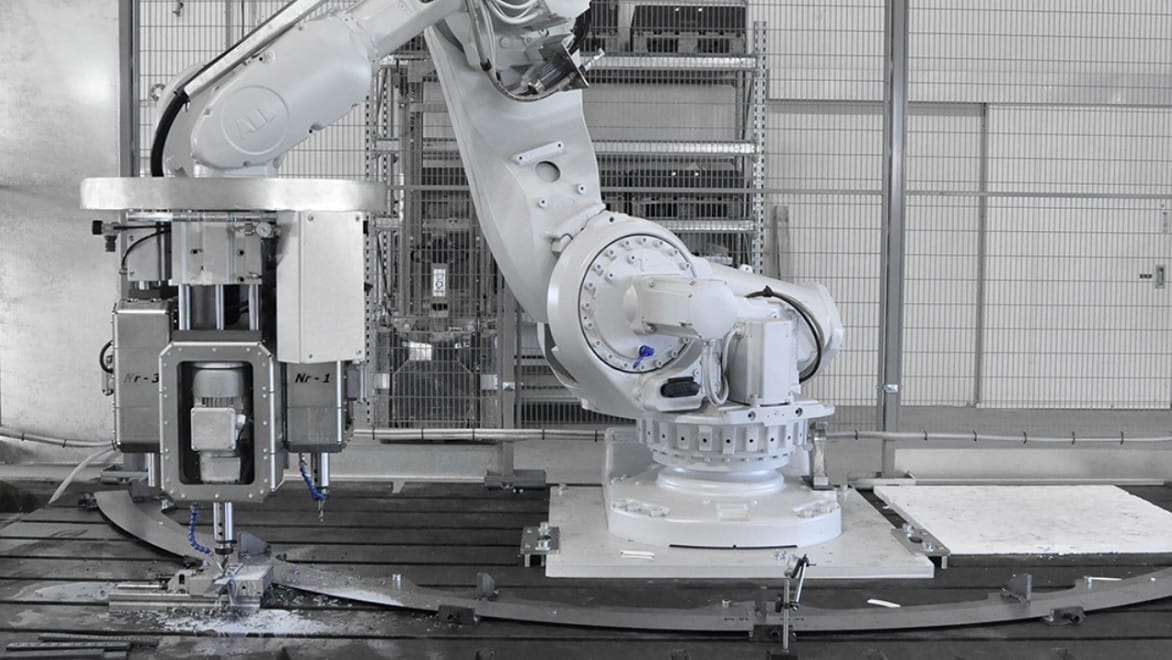

Odico’s robots boost in-factory productivity for companies specialising in smaller production runs. Image courtesy of Odico.

Managing a rigorous manufacturing process

In the past, drilling holes in something as big as a wind turbine blade would have been done manually. A human operator running a large drilling unit would need to ensure that each hole met exacting specifications for type, shape, depth, diameter, location and quality. The drilling unit itself had to be perfectly calibrated, fit and rigorously maintained. The person at the console had to have stamina and patience in this time-consuming process.

“Today, turbine blade profiles are moved by crane to drill each hole required,” says Anders Bundsgaard, founder and CEO of Odico. When operators finish drilling one hole, the profile has to be moved to a different position and fastened in place to fit the exact requirements. Because every profile needs up to 48 holes, about six profiles can be completed on a good day.

Odico Founder and CEO Anders Bundsgaard. Image courtesy of Odico.

Accommodating short-run manufacturing

Under these constraints, wind turbine production volumes tend to be small—hundreds of units versus the tens of thousands one would expect in a typical factory run. This allows engineers to continually make updates, refinements and improvements, but it also hinders standardisation. “For low-volume factory runs of 100 to 120, you can’t automate production in a traditional way,” Bundsgaard says. Every new order means going back to the drawing board. “And most robotic manufacturing systems have their roots in automotive, where you’re creating 100,000 cars or components at one time,” he adds. “Altering the design spec is difficult and usually requires someone with a design or engineering degree.”

To simplify this process, Odico created Drill Mate, a “beast of a robot” that can automatically drill precision patterns over and over again in complex metal profiles. Its modular architecture allows for quick, in-factory installation.

Drill Mate combines robotic drilling with the latest developments in computer-aided manufacturing (CAM). It’s designed for precise, heavy-duty work, with a multiphase drilling head and 6-axis manipulator that make the robot highly maneuverable. Each Drill Mate manufacturing robot has enough onboard computing capability to support a seamless file-to-factory workflow—which means designers can do rapid prototyping on the fly and frontline workers can quickly execute changes on-site. This enhanced programmability and flexibility benefits companies specialising in smaller production runs with fast turnarounds.

For Odico’s customers in Denmark’s booming renewable energy sector, which is set to increase wind power production by nearly 80% in 2024, those capabilities are boosting productivity and enabling agile, continuous improvement.

Manufacturing from a tablet

To refine the company’s offerings to this growing market, Bundsgaard and his product development team experimented with ways to embed Drill Mate more seamlessly into a standard CAM workflow and make it even easier for frontline workers to execute changes to a drilling spec.

Odico worked with Autodesk to integrate Drill Mate with Fusion 360. A few taps on a tablet and changes to drilling co-ordinates and requirements can be executed on the factory floor using Fusion 360’s CAM interface.

“For a young, dynamic industry like renewable energy with wind turbines, it’s in the DNA of design teams to continually innovate and improve,” Bundsgaard says. With our new system, anyone who can use a CAD/CAM interface can make changes in a matter of hours.”

Autodesk worked with Odico to integrate Drill Mate with Fusion 360. Image courtesy of Odico.

Improving productivity while saving jobs

So far, Odico’s robot deployment has delivered impressive results. Using the previous manual system and machinery, wind turbine manufacturing clients could typically complete six profiles a day. With Odico’s solution, they can drill 18 profiles—three times the typical industry output.

But even with such an impressive jump in productivity, Bundsgaard doesn’t think robots have to upset the workplace balance between human and machine. “Robots are saving manufacturing jobs,” he says. “At the moment, we risk being in a race to the bottom with low-wage markets. The people that’s going to hurt most are the workers on the front line. By making robots more adaptable to individual needs, we’re going where the market is headed. Upskilling is going to be necessary, of course, but instead of being replaced, we see job roles evolving to match a broader range of robotics applications.”

In Bundsgaard’s view, robotic automation isn’t killing jobs but changing the way humans and devices work together.

A partnership between humans and machines

The World Economic Forum’s Future of Jobs Report 2020 shows that an increasing number of employers agree with Bundsgaard: It estimates that although 85 million jobs may be displaced by a shift in the division of labour between humans and machines by 2025, 97 million new roles may also emerge—roles that are more adapted to the new division of labour among humans, machines and algorithms.

This transformation will almost certainly include more portable and agile solutions like Odico’s pop-up Factory on the Fly, a mini manufacturing facility housed in a portable trailer. Designed for the construction industry, it promises to let anyone safely and easily use robots to construct building elements with a tablet. With it, manufacturing can be done close to the supply chain, reducing the need to deliver parts halfway across the planet.

Odico’s technology shifts the time-consuming process of calibration and fitting required for precision drilling to robots like Drill Mate. Image courtesy of Odico.

“For us, the dream scenario is being able to hand control over technology to the people on the factory floor or at the construction site. For that to happen, it’s vital that these tools keep their user-friendliness. Ideally, you want to be able to take someone from the workshop and train them up in 15 minutes and then let them run with it.”

—Anders Bundsgaard, Founder and CEO, Odico

Related products

Learn more