KOLB DESIGN TECHNOLOGY

Feat of clay: Using digital tools to cut cycle times in clay modelling.

CUSTOMER STORY

Share this story

Autodesk enable Kolb to make clay modelling fit for 21st Century design and development.

Automotive design and development has been revolutionized by virtual reality (VR) and augmented reality (AR). Designers across the world have been able to work together in real time on designs that can be shared and seen in holographic studios, whether in Sydney, Australia; Kidlington, England; or Detroit, Illinois.

Applications like Autodesk Alias and VRED have enabled collaboration across the world on ‘single versions of the truth’: shared designs that are always at the same stage and incorporate all iterations and developments by authorized personnel, wherever and whenever made.

But even in a digital world, there is still a role and a need for physical clay modelling.

Why Clay?

Original Equipment Manufacturers (OEMs) like Jaguar Land Rover make extensive use of clay models in design and development. The reason is straightforward, a car’s appearance is about how it looks under illumination, in different lighting conditions, from bright sunlight to artificial streetlighting. A physical model will give a clearer impression, emotion and conection than any simulation.

Modelling ‘clay’ is perhaps more widely recognized as Plasticine; the squishy material from children’s playrooms. It is moldable and doesn’t dry out, making it the ideal medium for the manifestation of car design in sculpting, especially in processes that can take days, weeks or even months.

It is not always ‘the first shot that hits’. Clay can be removed, added to, reshaped and reprofiled. New ideas can be tried relatively easily and quickly.

Clay models continue to be used as a collaboration tool where everyone can get around the car and brainstorm three-dimensionally.

The need for speed

Design cycles are getting shorter. Manual sculpting is very time consuming; a 10% scale model can take several weeks to make by hand and a full-size model, even longer. This is simply not practical in an era when the pace of that change is accelerating.

A full-size clay model is constructed on a steel frame – the same one may be used several times, so long as the dimensions of cars being modelled are similar. A styrofoam blank is then attached. It will usually be milled outside the studio, in order to keep foam dust out of the working area.

“Clay will be warmed to 60 °C and applied manually to the steel and foam framework, to a depth of between 4 and 10cm,” said Erwin Nutz, Managing Director of Kolb Design Technology. “It will be shaped and milled after being cooled to room temperature."

Once the shape has been sculpted, foil will be applied to make it look like the real thing, complete with windows, lights and alloy wheels.

Automating artistry

The methodology and tooling used by clay modelers who are highly-skilled sculptors has changed and evolved.

“Manually-operated coordinate measuring machines (CMMs) were (and are still) used to transfer dimensions from the drawing to the model, and to mirror shapes and surfaces sculptured on one half side to the other side,” Erwin said. “One modeler would touch points on the finished side with his CMM, read the X,Y,Z coordinates of a particular point and call the values to a colleague on the other side, who transfers that point in the unshaped clay with a scribing needle on another manual CMM, point by point, over a period of days or weeks.”

A milling tool is a more efficient way to build the other half of the vehicle. The next step forward was to put the CMM points into a CNC program and run motorized milling machines. 1:1 Clay models where previously done by large, gantry-mounted equipment but Kolb has taken things several steps down the road.

This is a world where technical expertise and craftmanship come together.

Kolb takes the next step

“Milling CMMs now provide the opportunity to combine milling and sculpting by hand at the same central creative area in the studio, without moving the model,” Erwin explained. “However, CMMs with adapted milling heads are not particularly efficient and the quality of the milled surface is not to the required standard. The base machine is designed for measuring, not milling.” Kolb design milling machines are designed from outset for milling and focused on the studio environment.

“If you have a full CNC file of the complete car you can mill it in one set, depending on the machine type. Mirroring from one half to the other transfers the designers’ and modelers’ creativity more easily,” he said.

Fusing digitial to physical

While all OEMs and independent studios have their own particular methods, the process will tend to follow the same general path.

It begins with an idea, which is rendered into a sketch, which is transferred using Autodesk software into a digital form.

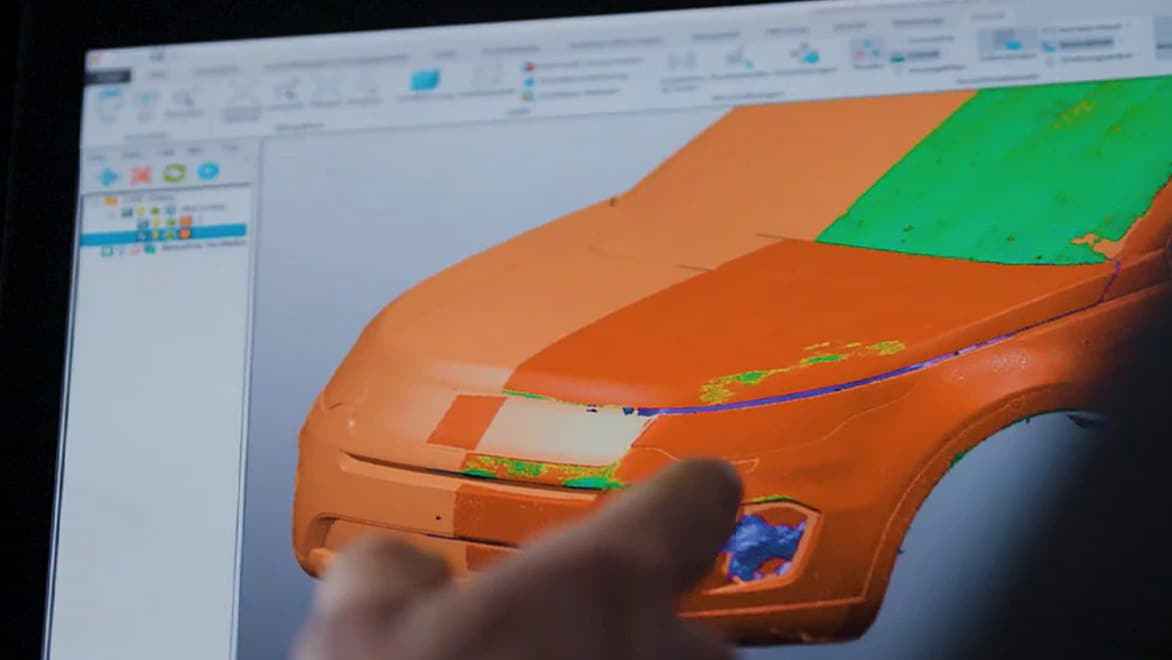

“The advanced way of making a model is to prepare an Autodesk PowerMill CNC file,” Erwin continued. “Half of it will be milled; the shapes and surfaces will be evaluated and any initial changes will be reformed manually, by the modelers.

The amendments will then be scanned and the data re-engineered back into a CNC file ready for milling the other side using Autodesk PowerMill. The surfaces will be finished by hand, ready for the application of paint, lacquer or foil.” Other features, such as mirrors, door-handles, front and rear lights, wheels and tires will be 3D printed or specially molded. The finished model will then be presented to the Board for approval.

PowerInspect and PowerMill files generated from the final clay model will be used in the next stages of the manufacturing process, including cubing, tool design, jig fixtures, and powertrain production.

Autodesk’s PowerMill and PowerInspect software serves to reduce material waste, speed up design to manufacturing, while running the KOLB machine with ease.

Time waits for no-one

The point cannot be emphasized too strongly: speed is of the essence.

“How long the milling process takes depends on the model. Producing a full-size SUV, for example, finished on both sides, rough and fine cut and with good surface quality, will take 20 to 30 hours, exceptionally cutting cycle times in clay modelling” Erwin said.

Integration and automation for accelerated production

Kolb’s range of specialist machines for creating clay models are of a scale and sophistication suitable to be used within design studios and enable models to be produced, amended and finalized much faster while reducing material waste.

They use Autodesk software to mill the entire model from a single clay piece; to machine a portion of it, or even two different versions on the same piece, so that they can be compared side by side – quite literally.

The difference between fully-automated milling and conventional processes is clearly phenomenal. The speed of integrated software and advanced modeling machinery makes the creation of new versions of clay models and the incorporation of changes fast and accurate.

Leading manufacturer of clay milling machines Kolb are challenging the status quo for leading edge vehicle modelling. Together with Autodesk, the company is shaping the future of design studios.

Are you ready to secure your place in the future of automotive design?

Together with Autodesk, you can shape the future of your design studio.