Project | 04: Make a model engine crank soft jaw

This is project 4 of 11 in the model engine project series.

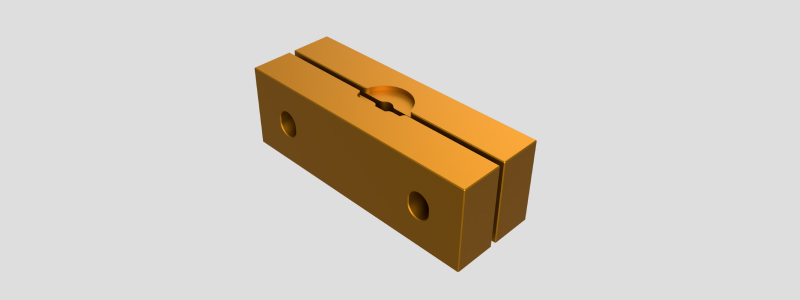

Create another work holding part. Model, program toolpaths, and machine a crank soft jaw.

Overview

Using the model and engineering drawings provided, set up and program toolpaths for the crank soft jaw.

Project scenario:

A customer has asked your company to redesign a model engine assembly and to machine a prototype. They have provided engineering drawings of the original. This project requires you to model the crank soft jaw to hold the crank during final machining operations. To find your soft jaw dimensions, use the supplied engineering drawing or source a soft jaw model that matches the soft jaws used in your shop Use the crank engineering drawing and model as a reference for the soft jaw geometry.

The company also provided engineering drawings of the original parts as well as a CAD model and would like to prototype all components of the engine assembly. This requires you to set up and program toolpaths for the crank soft jaw provided. Begin with the supplied model and engineering drawing. Consider how the soft jaws are clamped during machining and ensure any tools used have adequate access to geometry. Sample process plans, setup sheets, cutting data, and inspection reports are provided but use your judgment, the tools, and machines you have available, and your knowledge to complete the project.