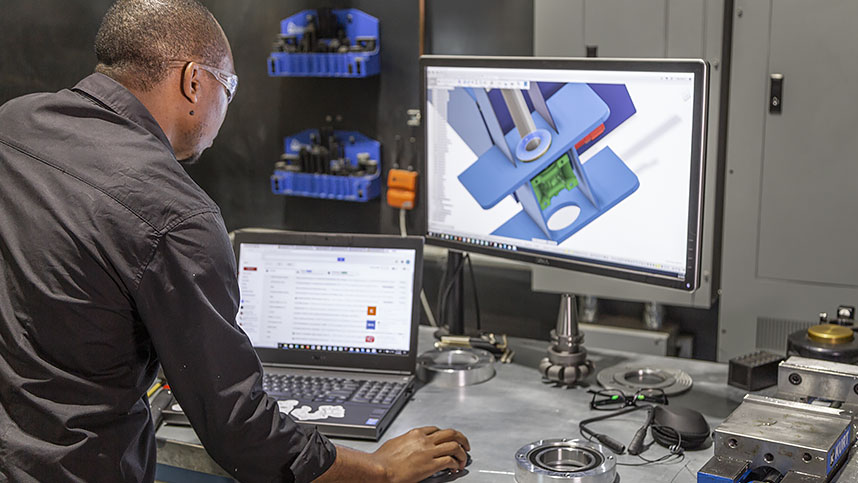

CAM and Design for Manufacturing for Milling

The design for manufacturing process puts manufacturing at the core of a design, focusing on potential problems in the design phase, and prioritizing how parts are made. In many cases, the end-product is made up of an assembly of different pieces to simplify manufacturing or to achieve specific design goals. Each piece represents a certain tolerance, and might not work together if not accounted for in the design.

Take a deeper look at leading-edge technologies and workflows for design for manufacturing, production drawings, and toolpaths to cut parts on a CNC mill. With increasing demands asked on the job, these skills help you adapt and solve tough challenges faced by the next generation of innovators. Hiring managers are looking for next generation innovators to solve tomorrow’s challenges and make an impact. This course will help you do just that.

After completing this course, you’ll be able to:

- Inspect a multicomponent assembly.

- Identify manufacturing methods based on part inspection.

- Create detailed drawings for manufacturing.

- Practice creating toolpaths for manufacture.

Course modules

Getting started

Create detailed drawings for production and identify critical features or aspects of a design on a drawing.

Learn about the required tools and fixturing needed to CNC mill a part.

Create toolpaths for a CNC Mill to better understand the requirements when designing parts to be manufactured.

Learn the toolpaths required to machine complex 3D shapes.

Course challenge exercise

Ready to test your knowledge?

Announcements

This course was updated September 2022.

Some of the changes to this course include:

- The proficiency level of this course has changed from Associate to Professional.