Keyboard ALT + g to toggle grid overlay

What is sheet metal software?

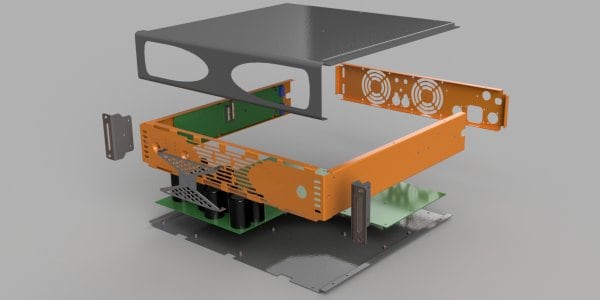

Sheet metal design software considers the fabrication methods needed for manufacturing. As you create flanges and add bends, the sheet metal design software will accurately represent the flat pattern required. The flat pattern can be used to document and manufacture associatively as the design changes.

Sheet metal design tools

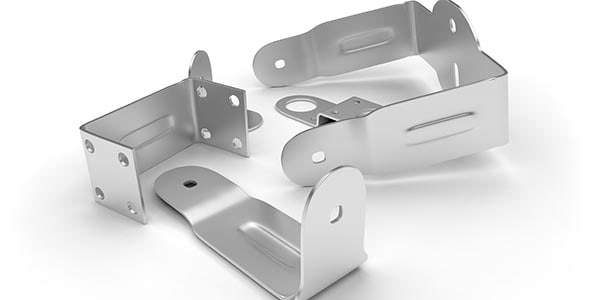

FLANGES

A flange is a common sheet metal feature, which consists of a bend connected to stationary face, along a straight edge.

BEND CALCULATIONS

Bend calculations ensure the correct length is calculated when a sheet metal design is manufactured flat then bent into its finished state based on a K-Factor.

GAUGE TABLES

Gauge tables define the thickness of sheet metal. There are several gauge tables depending on the material of the sheet metal, which specify the thickness for both inches and millimetres.

Sheet metal design and manufacturing software

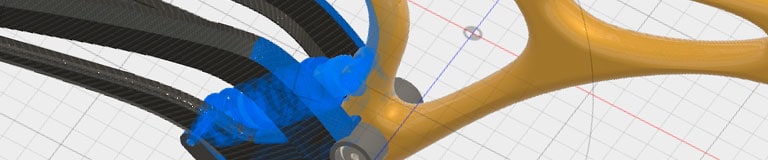

Cloud-based 3D CAD/CAM/CAE software for industrial and product design

Mechanical design and 3D CAD software for product development

True shape nesting software for Inventor to optimise yield from flat raw material

CNC postprocessing software for nesting and cutting

Why use Fusion 360 for sheet metal design?

Fusion 360 is a next generation, cloud connected CAD, CAM and CAE software that can take you from concept to production.

-

Connected design to manufacturing

Design, test, document and fabricate in a single integrated tool.

-

Cloud

Access your data anywhere on any device to stay connected throughout the product development process.

-

Ease of use

Use the single flange tool to make just about anything, including base flanges, edge flanges, miter flanges and contour flanges.

What are the manufacturing methods for sheet metal designs?

WATER JET

Pressurised water mixed with abrasives can cut through stainless steel, Inconel, titanium, aluminium, tool steel, ceramics, granite and armour plate, with a clean edge finish.

LASER

A gas laser, such as a CO2, is transmitted through a beam, guided by mirrors and directed at the material at an extremely high level of precision.

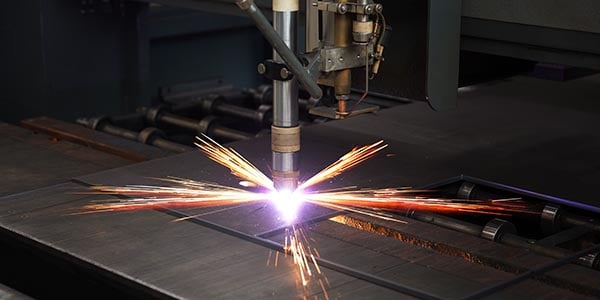

PLASMA

The plasma process uses electrically conductive gas to transfer energy from a torch to the material being cut. Developed for metals that could not be flame cut, such as stainless steel, aluminium and copper.

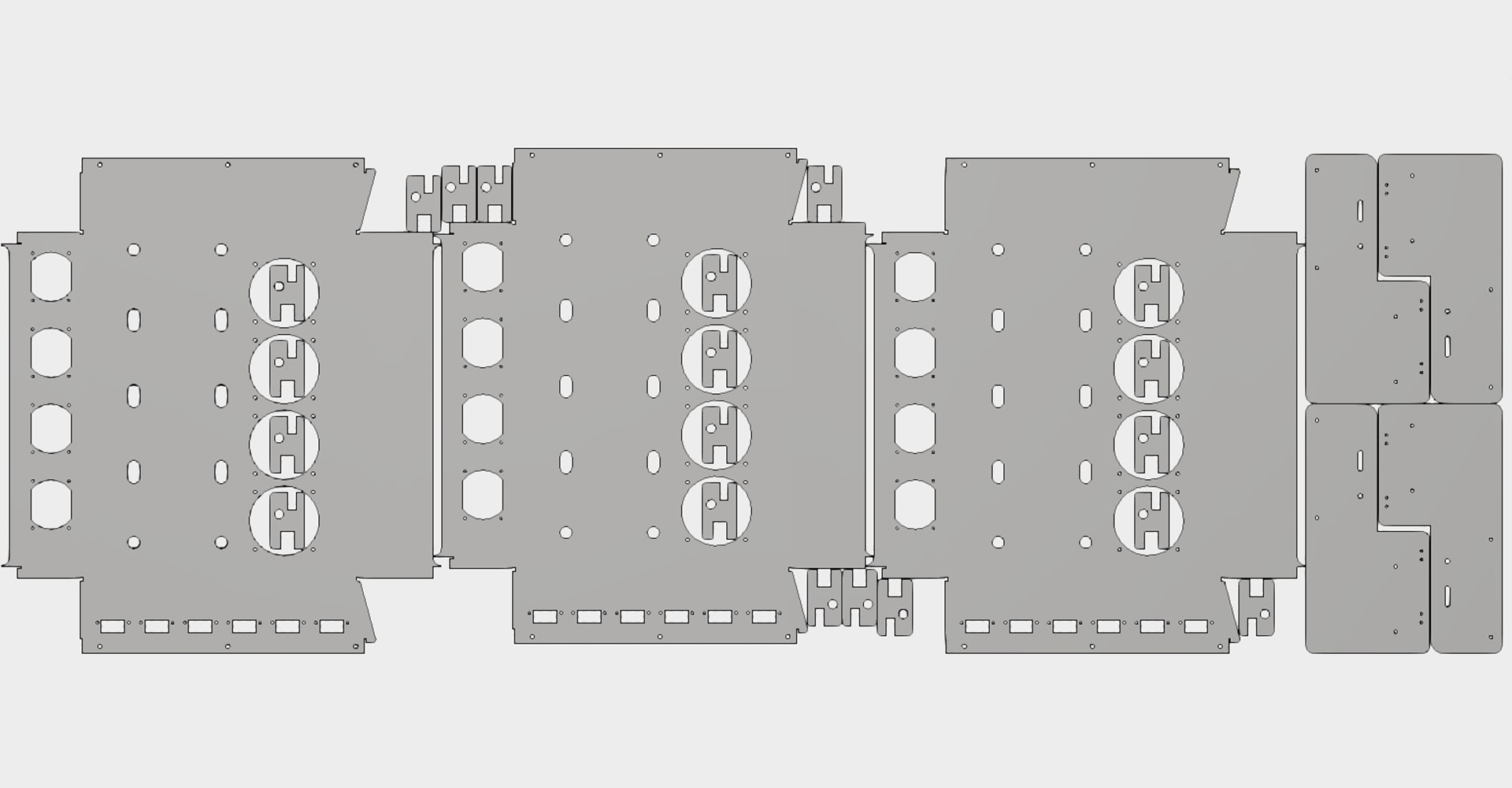

Nesting sheet metal

To reduce scrap and increase efficiency, work pieces need to be "nested" onto the stock. Use the nesting utility in Inventor to optimise yield from flat raw material.

Sheet metal design tutorials

SHEET METAL WITH FUSION 360

Learn the features and workflows needed for brake press sheet metal design in this Autodesk University online class.

SHEET METAL LEARNING RESOURCES

Learn the foundational concepts of sheet metal design and manufacturing in Fusion 360 through these learning courses.

CARDBOARD BOX DESIGN WITH SHEET METAL

Learn how to create parametric cardboard packaging using sheet metal tools.