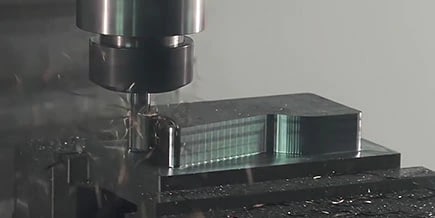

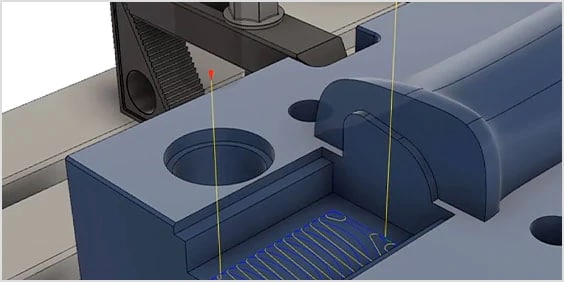

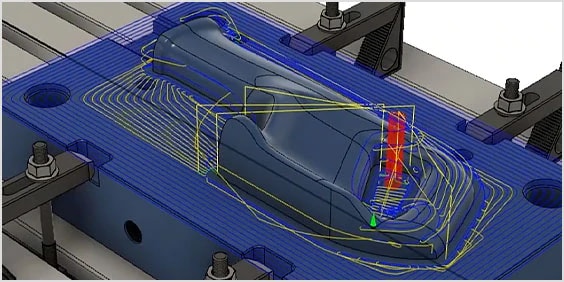

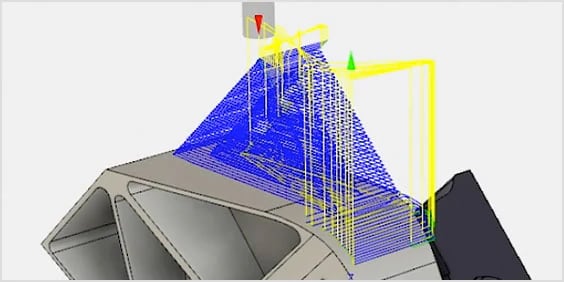

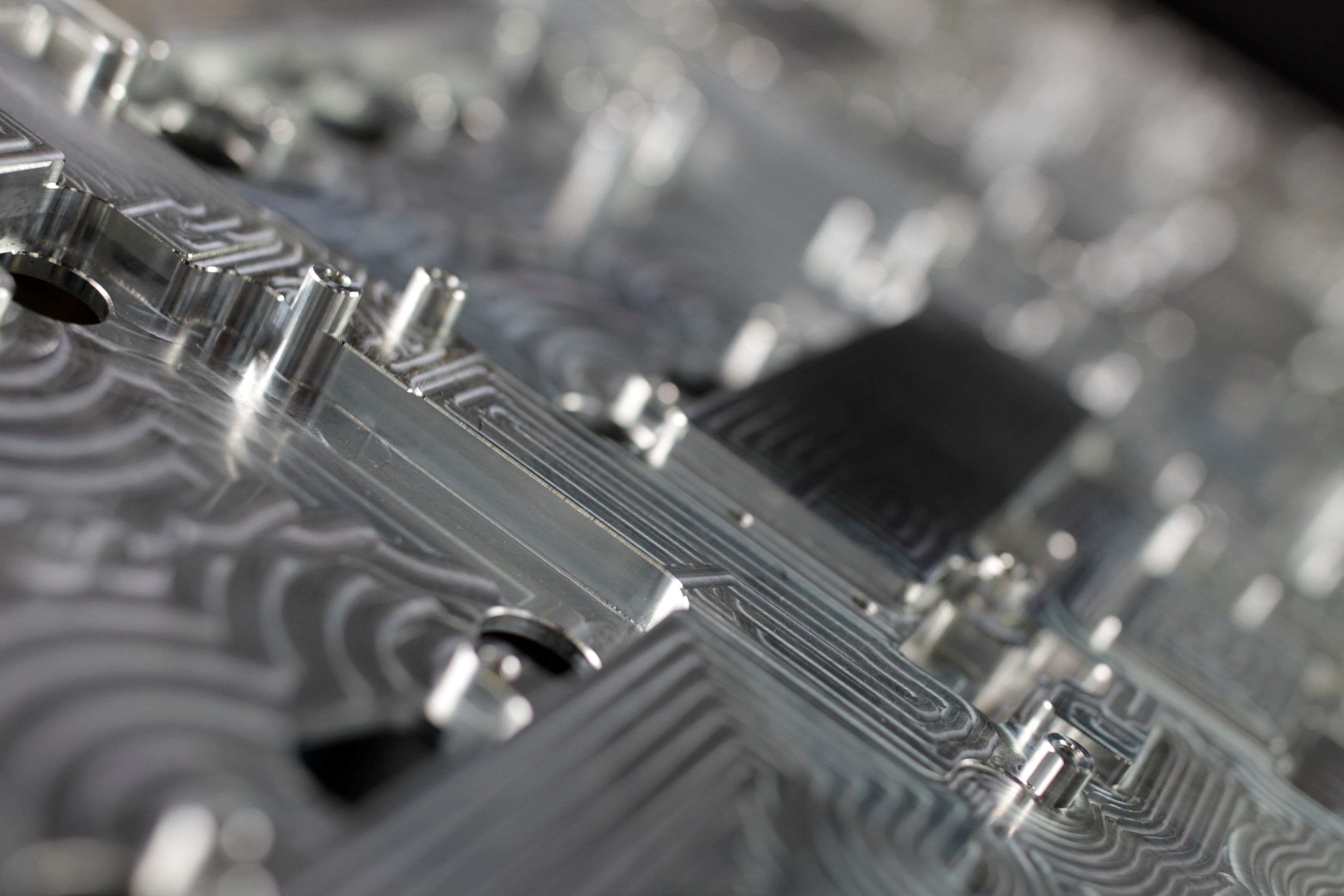

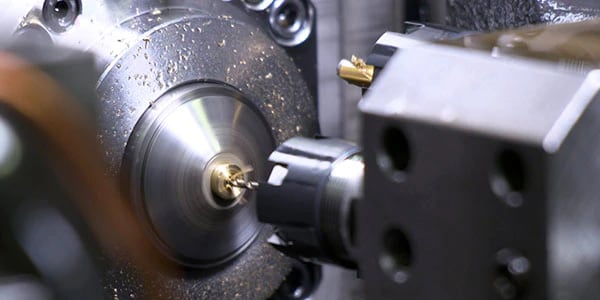

CNC programming (Computer Numerical Control Programming) is used by manufacturers to create program instructions for computers to control a machine tool. CNC is highly involved in the manufacturing process and improves automation as well as flexibility.

AUTODESK FUSION 360

CNC PROGRAMMING

CNC programming is an arcane and daunting task. Never write your own CNC programming by hand again. Generate G-code with Fusion 360 effortlessly and make parts faster the first time.